Toyota Corolla Cross: Purge Valve

Removal

REMOVAL

CAUTION / NOTICE / HINT

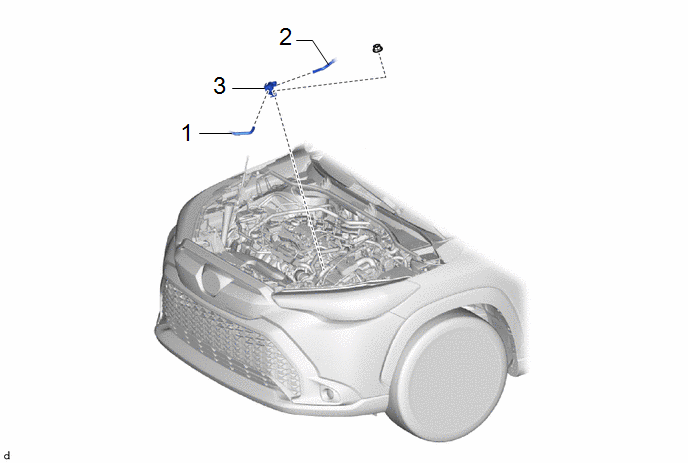

COMPONENTS (REMOVAL)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | NO. 2 FUEL VAPOR FEED HOSE |

23827A | - |

- | - |

|

2 | FUEL VAPOR FEED HOSE ASSEMBLY |

23820 | - |

- | - |

|

3 | PURGE VALVE (PURGE VSV) |

25860 | - |

- | - |

PROCEDURE

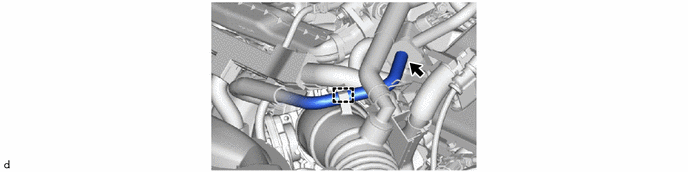

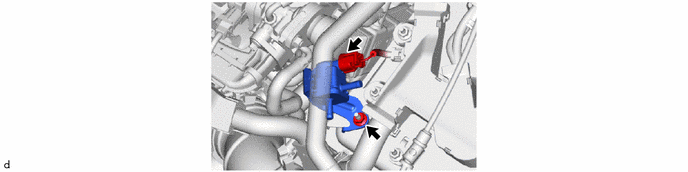

1. DISCONNECT NO. 2 FUEL VAPOR FEED HOSE

2. DISCONNECT FUEL VAPOR FEED HOSE ASSEMBLY

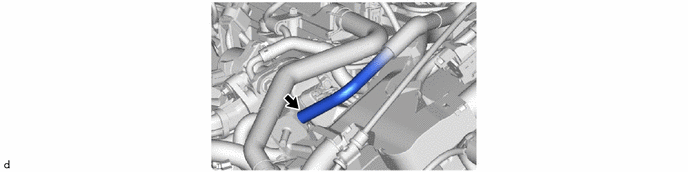

3. REMOVE PURGE VALVE (PURGE VSV)

Inspection

INSPECTION

PROCEDURE

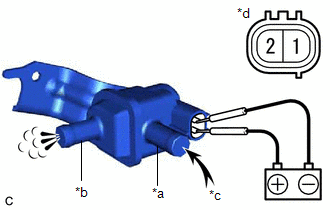

1. INSPECT PURGE VALVE (PURGE VSV)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 - 2 | 20°C (68°F) |

23 to 26 Ω |

If the result is not as specified, replace the purge valve (purge VSV).

| (b) Apply battery voltage between the terminals of the purge valve (purge VSV) and check that the following occurs when blowing air into the port (E). OK:

If the result is not as specified, replace the purge valve (purge VSV). |

|

Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | PURGE VALVE (PURGE VSV) |

25860 | - |

- | - |

|

2 | FUEL VAPOR FEED HOSE ASSEMBLY |

23820 | - |

- | - |

|

3 | NO. 2 FUEL VAPOR FEED HOSE |

23827A | - |

- | - |

PROCEDURE

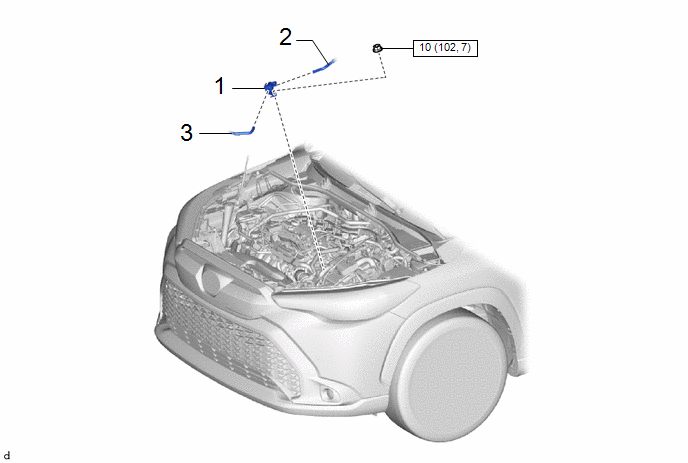

1. INSTALL PURGE VALVE (PURGE VSV)

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

2. CONNECT FUEL VAPOR FEED HOSE ASSEMBLY

3. CONNECT NO. 2 FUEL VAPOR FEED HOSE