Toyota Corolla Cross: Pressure Control Solenoid "B" Actuator Stuck Off (P07757F)

DESCRIPTION

Using the current from the TCM, the shift solenoid valve SL2 controls the C2 clutch pressure in accordance with the requested shift mode.

When the TCM requests the shift mode to be changed to belt mode, the C2 clutch is engaged and the input torque is transmitted to the output shaft via the steel belt.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P07757F |

Pressure Control Solenoid "B" Actuator Stuck Off |

Any of the following conditions are met (2-trip detection logic):

|

|

Comes on |

DTC stored |

SAE Code: P0776 |

MONITOR DESCRIPTION

- When the TCM requests the shift mode to be changed to belt mode, the shift

solenoid valve SL2 is turned ON and the C2 clutch is engaged. As a result, the

transmission revolution sensor (NSS) signal becomes equal to the transmission

revolution sensor (NOUT) signal.

By comparing the signals indicating the secondary pulley revolution (speed) and output shaft revolution (speed), the TCM judges if the shift mode is belt mode or not.

When the TCM requests the shift mode to be changed to belt mode, if the difference between the transmission revolution sensor (NSS) and (NOUT) signals is more than 300 rpm, it determines the shift solenoid valve SL2 is malfunctioning, illuminates the MIL and stores this DTC.

- Under normal conditions, when the TCM requests the shift mode to be changed

to gear mode, line pressure is applied from the shift solenoid SL1 to engage

the C1 clutch and gear mode is entered.

When the shift solenoid valve SL2 is stuck ON, if the TCM requests the shift mode to be changed to gear mode, line pressure is applied to the clutch apply control valve from the shift solenoid valve SL2 and in turn line pressure to the C1 clutch is blocked.

As a result, the C1 clutch cannot be engaged and the shift mode cannot be changed.

In this case, when the TCM requests the shift mode to be changed to gear mode, it detects that gear mode cannot be entered (the C1 clutch is not engaged and the difference between the transmission revolution sensor (NT) signal and transmission revolution sensor (NC1) signal exceeds the threshold) and determines that the shift solenoid valve SL2 is stuck ON, illuminates the MIL and stores a DTC.

SL2 Stuck ON Detection Condition:

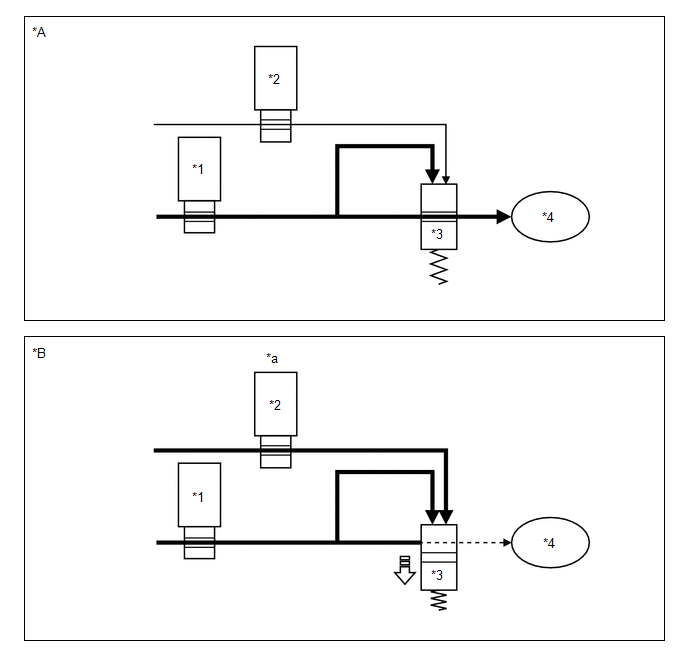

*A

TCM commands C1 clutch engagement when shift solenoid valve SL2 normal

*B

TCM commands C1 clutch engagement when shift solenoid valve SL2 stuck ON

*1

Shift Solenoid Valve SL1

*2

Shift Solenoid Valve SL2

*3

Clutch Apply Control Valve

*4

C1 Clutch

*a

Shift solenoid valve SL2 stuck ON

-

-

.png)

Oil Pressure Flow

Valve Movement

MONITOR STRATEGY

|

Related DTCs |

P0776: Pressure control solenoid "B" (Shift solenoid valve SL2)/Functional check |

|

Required sensors/Components |

Crankshaft position sensor Transmission revolution sensor (NT) Transmission revolution sensor (NC1) Transmission revolution sensor (NSS) Transmission revolution sensor (NOUT) CVT fluid temperature sensor Engine coolant temperature sensor Oil pressure sensor Shift solenoid valve SL1 Shift solenoid valve SL2 Shift solenoid valve SLP Shift solenoid valve SLS |

|

Frequency of operation |

Continuous |

|

Duration |

OFF malfunction (A): 2 sec. OFF malfunction (B): - OFF malfunction (C): 1 sec. ON malfunction (A): 1 sec. ON malfunction (B): 2 sec. ON malfunction (C): 1 sec. |

|

MIL operation |

2 driving cycles |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All|

ETC system (Electronic throttle control system) |

Not system down (MIL illuminated by following codes: P0121, P0122, P0123, P0222, P0223, P0604, P0606, P0607, P060D, P060E, P0657, P0658, P1607, P16B0, P2102, P2103, P2111, P2112, P2119, P2135) |

|

KCS sensor circuit (Knock sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0327, P0328) |

|

ECT sensor circuit (Engine coolant temperature sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0117, P0118) |

|

IAT sensor circuit (Intake air temperature sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0112, P0113) |

|

Crankshaft position sensor "A" circuit (Crankshaft position sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0335, P0337, P0338) |

|

CAN communication between ECM and TCM |

Not system down (MIL illuminated by following codes: U0100, U0101) |

|

Low voltage flag |

OFF |

|

Pressure control solenoid "J" circuit (Shift solenoid valve SLP) |

Not circuit malfunction (MIL illuminated by following codes: P2826, P2827) |

|

Pressure control solenoid "K" circuit (Shift solenoid valve SLS) |

Not circuit malfunction (MIL illuminated by following codes: P282F, P2830) |

|

Pressure control solenoid "A" circuit (Shift solenoid valve SL1) |

Not circuit malfunction (MIL illuminated by following codes: P0962, P0963) |

|

Pressure control solenoid "B" circuit (Shift solenoid valve SL2) |

Not circuit malfunction (MIL illuminated by following codes: P0966, P0967) |

|

Turbine speed sensor "A" circuit (Transmission revolution sensor (NT)) |

Not circuit malfunction (MIL illuminated by following codes: P0717, P07BF, P07C0) |

|

Intermediate shaft speed sensor "C" circuit (Transmission revolution sensor (NSS)) |

Not circuit malfunction (MIL illuminated by following codes: P07C9, P07CA, P2751) |

|

Gear shift position circuit |

Not circuit malfunction (MIL illuminated by following codes: P0916, P0917) |

|

Output speed sensor circuit (Transmission revolution sensor (NOUT)) |

Not circuit malfunction (MIL illuminated by following codes: P0722, P077C, P077D) |

|

Intermediate shaft speed sensor "B" circuit (Transmission revolution sensor (NC1)) |

Not circuit malfunction (MIL illuminated by following codes: P07C7, P07C8, P2747) |

|

Engine |

Starting |

|

Shift solenoid valve SLP |

Operating shift control by TCM command |

|

Engine speed |

500 rpm or more |

|

Secondary sheave speed |

More than 0 rpm |

|

Any of the following conditions are met: (a) or (b) |

- |

|

(a) Output speed |

More than 0 rpm |

|

(b) All of the following conditions are met |

- |

|

- Output speed |

0 rpm |

|

- Gear mode clutch speed |

0 rpm |

|

- Synchronizer |

Engaged |

|

Shift solenoid valve SLP |

Operating shift control by TCM command |

|

Engine speed |

500 rpm or more |

|

Synchronizer |

Engaged |

|

Turbine torque |

40 N*m (408 kgf*cm, 30 ft.*lbf) or more |

|

Accelerator pedal release flag |

OFF |

|

Engine speed |

500 rpm or more |

|

Shift position |

"D" or "B" |

|

Secondary sheave torque |

40 N*m (408 kgf*cm, 30 ft.*lbf) or more |

|

Accelerator pedal release flag |

OFF |

|

Output speed |

More than 80 rpm |

|

Shift solenoid valve SLP |

Operating shift control by TCM command |

|

Engine speed |

500 rpm or more |

|

Synchronizer |

Engaged |

|

Turbine speed |

More than 0 rpm |

|

Any of the following conditions are met: (a) or (b) |

- |

|

(a) Gear mode clutch speed |

More than 0 rpm |

|

(b) All of the following conditions are met |

- |

|

- Gear mode clutch speed |

0 rpm |

|

- Output speed |

0 rpm |

|

Engine speed |

550 rpm or more |

|

Transmission fluid temperature |

-10°C (14°F) or more |

|

Time after following condition is met |

0.5 sec. or more |

|

- l Variation of the accelerator pedal angle l (within 32.768 msec.) |

Less than 0.5% |

|

Shift solenoid valve SLS |

Operating clamping pressure control by TCM command |

|

ECT |

60°C (140°F) or more |

|

Spark advance from MAX. retard timing by KCS control |

0°CA or more |

|

Gear and belt mode clutch |

Either engagement or disengagement |

|

Shift solenoid valve SLP |

Operating shift control by TCM command |

|

Engine speed |

500 rpm or more |

|

Secondary sheave torque |

40 N*m (408 kgf*cm, 30 ft.*lbf) or more |

|

Accelerator pedal release flag |

OFF |

TYPICAL MALFUNCTION THRESHOLDS

OFF malfunction- Any of the following conditions are met: OFF malfunction (A) and (B) or

(A) and (C) OFF malfunction (A)

OFF malfunction (B) (after OFF malfunction (A) is met)TCM indicate belt mode clutch

Engagement

l Secondary sheave speed - Output speed l

More than 300 rpm

OFF malfunction (C) (after OFF malfunction (A) is met)TCM indicate gear mode clutch

Engagement

l Turbine Speed - Gear mode clutch speed l

Less than 25 rpm

Shift solenoid valve SLP

Operating belt mode clutch control by TCM command

Secondary sheave speed - Output speed

Less than 25 rpm

- All of the following conditions are met: ON malfunction (A), (B) and (C)

ON malfunction (A)

ON malfunction (B) (after ON malfunction (A) is met)TCM indicate gear mode clutch

Engagement

l Turbine Speed - Gear mode clutch speed l

More than 200 rpm

ON malfunction (C) (after ON malfunction (A) and (B) are met)Target clamping pressure

1.4 MPa (14.3 kgf/cm2, 203 psi) or more

l Actual clamping pressure - Target clamping pressure l

Less than 0.5 MPa (5.1 kgf/cm2, 73 psi)

TCM indicate belt mode clutch

Engagement

l Secondary sheave speed - Output speed l

Less than 25 rpm

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the Clear Permanent DTC procedure.

Click here

.gif)

.gif)

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the GTS on.

- Start the engine.

- Perform the D Position Shift Test inspection in Road Test. [*1]

Click here

.gif)

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P07757F.

- Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

CAUTION / NOTICE / HINT

NOTICE:

- Perform the universal trip to clear permanent DTCs.

Click here

.gif)

.gif)

- Perform registration and/or initialization when parts related to the continuously

variable transaxle system are replaced.

Click here

.gif)

- Check that no DTCs are stored after performing initialization.

Click here

.gif)

.gif)

HINT:

If any DTCs other than P07757F are output, perform troubleshooting for those DTCs first.

PROCEDURE

|

1. |

CHECK DTC OUTPUT (IN ADDITION TO DTC P07757F) |

(a) Enter the following menus:

Powertrain > Transmission > Trouble Codes(b) Read the DTCs using the GTS.

HINT:

- If DTC P077512 or P077514 is output, perform troubleshooting for that DTC first.

- If DTCs P077512 and P077514 are not output but DTC P281F00 is output, perform troubleshooting for DTC P281F00 first.

|

Result |

Proceed to |

|---|---|

|

Only DTC P07757F is output |

A |

|

DTC P07457F and P07757F are output |

B |

|

DTC P07757F and P077512 are output |

C |

|

DTC P07757F and P077514 are output |

D |

|

DTC P07757F and P281F00 are output |

E |

|

DTC P07757F and DTCs other than P07457F, P077512, P077514 and P281F00 are output |

F |

| B | .gif) |

GO TO STEP 5 |

| C | .gif) |

GO TO DTC CHART (DTC P077512) |

| D | .gif) |

GO TO DTC CHART (DTC P077514) |

| E | .gif) |

GO TO DTC CHART (DTC P281F00) |

| F | .gif) |

GO TO DTC CHART |

|

|

2. |

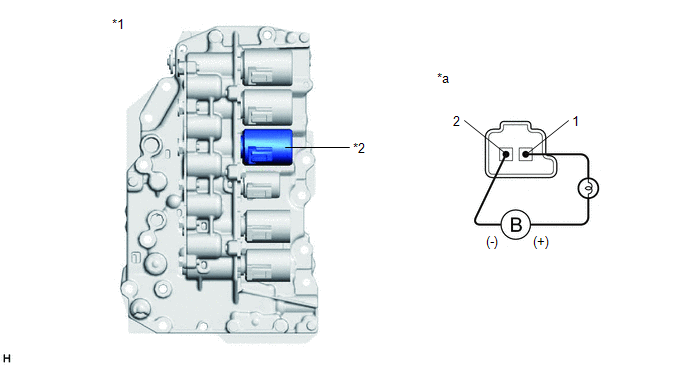

INSPECT TRANSMISSION VALVE BODY ASSEMBLY (SHIFT SOLENOID VALVE SL2) |

(a) Disconnect the transmission wire connector from the shift solenoid valve SL2.

Click here .gif)

|

*1 |

Transmission Valve Body Assembly |

*2 |

Shift Solenoid Valve SL2 |

|

*a |

Component without harness connected (Shift Solenoid Valve SL2) |

- |

- |

(b) Connect a positive (+) lead from the auxiliary battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the shift solenoid valve SL2 connector. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| NG | .gif) |

GO TO STEP 4 |

|

|

3. |

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

4. |

REPLACE TRANSMISSION VALVE BODY ASSEMBLY |

Click here .gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

5. |

INSPECT TRANSMISSION VALVE BODY ASSEMBLY (SHIFT SOLENOID VALVE SL1) |

(a) Disconnect the transmission wire connector from the shift solenoid valve SL1.

Click here .gif)

.png)

|

*1 |

Transmission Valve Body Assembly |

*2 |

Shift Solenoid Valve SL1 |

|

*a |

Component without harness connected (Shift Solenoid Valve SL1) |

- |

- |

(b) Connect a positive (+) lead from the auxiliary battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the shift solenoid valve SL1 connector. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK | .gif) |

GO TO STEP 2 |

|

|

6. |

REPLACE TRANSMISSION VALVE BODY ASSEMBLY |

Click here .gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

.gif)