Toyota Corolla Cross: Precaution

PRECAUTION

TROUBLESHOOTING PRECAUTION

NOTICE:

- Since the Dynamic Torque Control AWD system may be influenced by a malfunction in other systems, be sure to check for DTCs in the other systems.

- When removing and installing the 4WD ECU assembly and each sensor, be sure to check that the normal display is output in DTC output inspection after installing all the parts.

- When replacing the 4WD ECU assembly, always replace it with a new one.

- When the yaw rate and acceleration sensor (airbag ECU assembly) is replaced,

Reset Memory must be performed.

Click here

.gif)

AWD CONTROL PREVENTION MODE PROCEDURES FOR INSPECTION AND MAINTENANCE

(a) When using speedometer tester

NOTICE:

- Testers with a load setting mechanism for 2 wheels only (models with a power absorption mechanism for 2 wheels only: 2-wheel chassis dynamometer, or any combination testers such as 2-wheel chassis dynamometer with speedometer tester or brake tester) cannot be used by themselves.

- Perform the inspection on the front wheels.

- Do not start off, accelerate or decelerate suddenly.

- The vehicle speed should be 60 km/h (37 mph) or less. (When a free roller is in use, the vehicle speed should be 50 km/h (31 mph) or less)

- The driving time should be within 1 minute.

(1) Enter AWD control prevention mode using GTS or manual operation.

Click here .gif)

(2) Check that "AWD TEST MODE" is displayed on the multi-information display. (Check that AWD control is prohibited)

(3) Place the front wheels onto the roller.

(4) Place the rear wheels onto the free roller or safety stand.

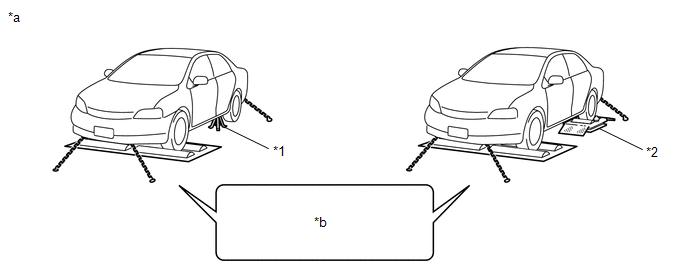

|

*1 |

Safety stand |

*2 |

Free roller |

|

*a |

When using drum tester |

*b |

AWD control prevention mode |

(5) Secure the vehicle with lock chains.

HINT:

The position of the lock chain in the illustration is for reference only.

(6) With the shift position in D, measure the vehicle speed while increasing the speed gradually.

(7) After measuring the vehicle speed, use the brake to gradually decrease the speed and stop the vehicle.

NOTICE:

Do not use the parking brake. If brake is applied only on the rear wheels during high engine speed, it may cause AWD function effectiveness to decline, drivetrain parts to malfunction or the vehicle to move unexpectedly.

(8) Canceling AWD control prevention mode.

Click here .gif)

NOTICE:

- Be sure to cancel AWD control prevention mode after the measurement.

- Do not drive the vehicle while in AWD control prevention mode.

(9) Check that the "AWD TEST MODE" is no longer displayed on the multi-information display. (AWD control prevention mode is canceled)

(b) When using brake tester

NOTICE:

- A tester with a load measurement mechanism cannot be used.

- A high-speed type brake tester cannot be used.

(1) Enter AWD control prevention mode using GTS or manual operation.

Click here .gif)

(2) Check that "AWD TEST MODE" is displayed on the multi-information display. (Check that AWD control is prohibited)

(3) Place the wheels to be tested (front or rear) onto the roller.

(4) Put the shift position in N.

(5) Drive the roller of the brake tester and measure.

HINT:

The driving time should be within 1 minute.

(6) Canceling AWD control prevention mode.

Click here .gif)

NOTICE:

- Be sure to cancel AWD control prevention mode after the measurement.

- Do not drive the vehicle while in AWD control prevention mode.

(7) Check that the "AWD TEST MODE" is no longer displayed on the multi-information display. (AWD control prevention mode is canceled)

(c) When using chassis dynamometer

(1) Enter AWD control prevention mode using GTS or manual operation.

Click here .gif)

(2) Check that "AWD TEST MODE" is displayed on the multi-information display. (Check that AWD control is prohibited)

(3) Use the following methods to perform the test.

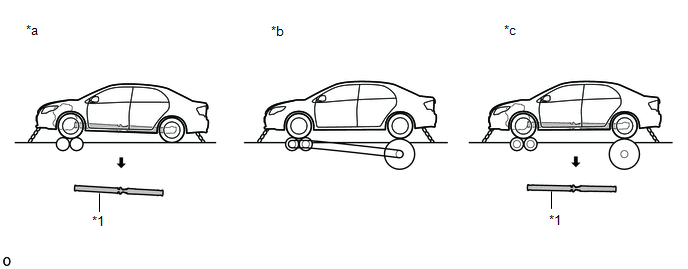

|

*1 |

Propeller Shaft Assembly |

- |

- |

|

*a |

2-wheel Chassis Dynamometer |

*b |

4-wheel Driven Chassis Dynamometer (Mechanical Front/back Synchronized Type) |

|

*c |

4-wheel Driven Chassis Dynamometer (Electric Front/back Synchronized Type) |

- |

- |

.png) |

Remove |

- |

- |

NOTICE:

- Do not suddenly accelerate or apply the brake.

- Failure to observe the following methods may cause AWD function effectiveness

to decline, drivetrain parts to malfunction or the vehicle to move unexpectedly.

Vehicle Condition

Chassis Dynamometer

Vehicle Speed, Test Time

Propeller Shaft Assembly

*a

(*1)

2-wheel Chassis Dynamometer

No limit

Remove

*b

4-wheel Driven Chassis Dynamometer (Mechanical Front/back Synchronized Type)

No limit

Normal

*c

(*1)(*2)

4-wheel Driven Chassis Dynamometer (Electric Front/back Synchronized Type)

No limit

Remove

NOTICE:

- (*1): Be sure to enter AWD control prevention mode in order to perform the test with the vehicle in front wheel drive. If performed under other conditions, "AWD System Overheated 2WD Mode Engaged" is displayed on the multi-information display and the drivetrain may be damaged.

- (*2): Do not use the electric front/back synchronized type 4-wheel driven chassis dynamometer with the propeller shaft assembly installed since the drivetrain may be damaged. (However, use with the propeller shaft assembly removed is possible)

(4) Canceling AWD control prevention mode.

Click here .gif)

NOTICE:

- Be sure to cancel AWD control prevention mode after the measurement.

- Do not drive the vehicle while in AWD control prevention mode.

(5) Check that the "AWD TEST MODE" is no longer displayed on the multi-information display. (AWD control prevention mode is canceled)

CAUTIONS FOR TOWING DYNAMIC TORQUE CONTROL AWD VEHICLE

(a) Tow the vehicle with all 4 wheels on the ground or lifted up. When towing the vehicle with all 4 wheels on the ground, limit the tow speed to 30 km/h (19 mph) or less and the tow distance to 80 km (50 miles) or less, and tow the vehicle in the forward direction.

NOTICE:

If the vehicle is towed above this speed and beyond this distance or is towed in reverse direction, the transaxle may be affected or damaged.

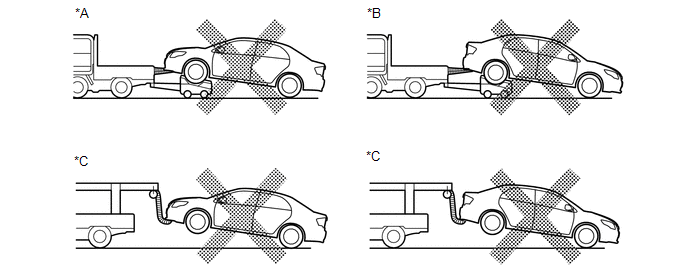

(b) Do not tow with only the front or rear wheels lifted up. If the driving system or drivetrain is malfunctioning, transport the vehicle with all 4 wheels lifted up.

|

*A |

Tow Truck (Rear Wheels on the Ground) |

*B |

Tow Truck (Front Wheels on the Ground) |

|

*C |

Tow Truck (Sling-type) |

- |

- |

NOTICE:

- Do not use a sling-type towing method. If a sling-type tow truck is used, damage may occur to the vehicle body.

- Towing with only the front wheels or rear wheels lifted up may damage drivetrain parts or cause the wheels to jump out of the tow truck.

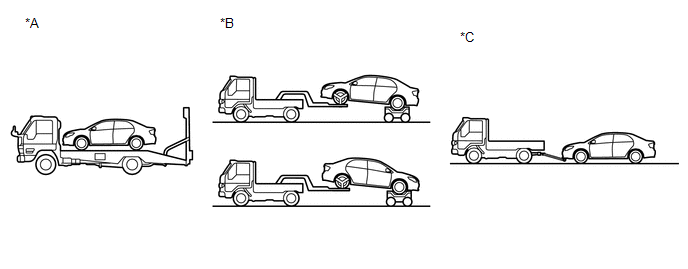

(c) Use one of the methods shown below to tow the vehicle.

|

*A |

Car Carrier |

*B |

Tow Truck (4 Wheels Lifted) |

|

*C |

Tow Truck (4 Wheels on the Ground) - Limit the tow speed to 30 km/h (19 mph) or less - Limit the tow distance to 80 km (50 miles) or less |

- |

- |

NOTICE:

- If there is a malfunction in the chassis or drivetrain, use the car carrier.

- When towing the vehicle, do not use any towing method other than those shown in the illustration.

|

Towing Method |

Parking Brake |

Transmission Shift Lever Position |

|---|---|---|

|

Car Carrier |

Parking brake applied* |

Any position |

|

Tow Truck (4 Wheels Lifted) |

Parking brake applied* |

Any position |

|

Tow Truck (4 Wheels on the Ground) |

Parking brake not applied |

Shift position in N |

CAUTION:

*: The braking force of the electric parking brake changes according to the tilt of the vehicle. When towing the vehicle, pull the parking brake switch 2 times (2 lock operations) to apply the maximum amount of braking force to prevent the wheels from moving unexpectedly.

HINT:

The steering lock cannot be released with the auxiliary battery fully depleted or the cable disconnected from the negative (-) auxiliary battery terminal.