Toyota Corolla Cross: Precaution

PRECAUTION

PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

NOTICE:

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here .gif)

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here .gif)

TROUBLESHOOTING PRECAUTION

(a) When there is a malfunction with terminal contact points or part installation problems, removal and installation of the suspected parts may return the system to normal either completely or temporarily.

(b) Before disconnecting a connector or removing and installing a component in order to narrow down the malfunctioning part, make sure to perform the following procedure.

- Check for and record any DTCs and Freeze Frame Data that were stored around the time that the malfunction occurred.

- If any open circuit DTCs related to intermittent (momentary interruptions)

malfunctions are output, check the intermittent monitor.

Click here

.gif)

NOTICE:

Before disconnecting connectors or fuses, turn the ignition switch off and wait 20 seconds or more*.

- *: Differs according to vehicle conditions

(c) Since the system may be influenced by malfunctions in systems other than the electronically controlled brake system, be sure to check for DTCs in other systems.

HANDLING PRECAUTION

(a) Always ensure that the ignition switch is off before removing the brake actuator assembly or a sensor unless specifically instructed by the Repair Manual.

(b) When replacing the brake actuator assembly, always replace it with a new one.

NOTICE:

Never use a brake actuator assembly from another vehicle, including new vehicles.

(c) If the brake actuator assembly or a sensor has been removed and installed, always perform a Dealer Mode (Signal Check) inspection and check for DTCs after completion of installation to confirm that the system is operating correctly.

(d) Do not remove and install any electronically controlled brake system components not specified by the Repair Manual or the system may not operate correctly due to loss of calibration.

(e) When performing diagnosis and repair for the electronically controlled brake system, follow all specified procedures and perform the necessary inspections after completion.

DTC PRECAUTION

(a) If the warning lights are illuminated due to a malfunction, the warning lights will only turn off for some DTCs when the malfunction is repaired and the DTCs are cleared.

(b) If warning lights are illuminated, it is necessary to follow the procedure to turn off the warning lights.

NOTICE:

- Use caution when operating the vehicle when the warning lights are illuminated as the system may not operate due to a fail-safe function.

- After clearing the DTCs, the DTCs will be stored again if the malfunction persists.

PRECAUTIONS FOR REMOVAL, INSTALLATION AND REPLACEMENT OF COMPONENTS

(a) After replacing certain components, it may be necessary to update the ECU security key.

Click here .gif)

(b) After replacing the skid control ECU (brake actuator assembly), perform "Calibration".

Click here .gif)

(c) After replacing or reinstalling the yaw rate and acceleration sensor (airbag ECU assembly), perform "Calibration" after performing "Reset Memory".

Click here .gif)

(d) After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here .gif)

(e) After replacing or removing and installing a speed sensor rotor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

Click here .gif)

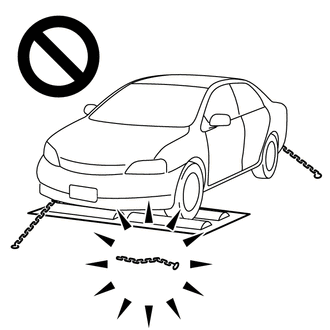

CHASSIS DYNAMOMETER PRECAUTION

When testing with a 2-wheel drum tester such as speedometer tester, combination tester for the speedometer and brakes, or chassis dynamometer, or when jacking up the front wheels and turning the wheels, perform the following procedure to enter Inspection Mode and disable the TRAC and VSC systems.

for entering inspection mode: Click here

.gif)

CAUTION:

- Do not use the drum tester with any of the lock chains disconnected.

- Using the drum tester with a lock chain disconnected could cause the vehicle to begin moving unexpectedly.

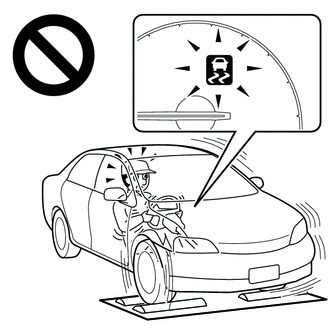

- Do not use the drum tester while the TRAC or VSC is able to operate.

- TRAC or VSC operation could cause the vehicle to begin moving unexpectedly.

DISABLING AND ENABLING OF TRAC AND VSC BY OPERATION OF VSC OFF SWITCH (COMBINATION SWITCH ASSEMBLY)

(a) Switching of mode

Operating the VSC OFF switch (combination switch assembly) switches the system between normal mode, TRAC off mode and VSC off mode.

(1) Normal mode

If the VSC OFF switch (combination switch assembly) is pressed when in TRAC off mode or VSC off mode, the system enters normal mode.

In normal mode, TRAC and VSC are enabled.

The system is set to normal mode when the ignition switch is turned to ON.

(2) TRAC off mode

If the VSC OFF switch (combination switch assembly) is pressed when in normal mode, the system enters TRAC off mode. When in TRAC off mode, TRAC is disabled and the multi-information display in the combination meter assembly displays "Traction Control Turned Off".

When the vehicle reaches a certain vehicle speed when in TRAC off mode, the system automatically returns to normal mode.

(3) VSC off mode

When the VSC OFF switch (combination switch assembly) is pressed and held for 3 seconds or more with the vehicle stopped, the system enters VSC off mode. When in VSC off mode, TRAC and VSC are disabled, the multi-information display in the combination meter assembly displays "Traction Control Turned Off" and the VSC OFF indicator light is illuminated.

The system does not automatically return to normal mode based on vehicle speed when in VSC off mode.

CAN COMMUNICATION SYSTEM PRECAUTION

(a) The CAN communication system is used for communication between the skid control ECU (brake actuator assembly), steering sensor, yaw rate and acceleration sensor (airbag ECU assembly) and other ECUs. If there is a malfunction in a CAN communication line, communication DTCs related to the affected systems will be stored.

(b) If any CAN communication DTCs are output, repair the malfunction, then troubleshoot the electronically controlled brake system while communication is normal.

(c) In order to enable CAN communication, a specific type of wiring is used for the CAN communication lines. The wiring used for each communication line is a twisted pair of wires that have an equal length. A bypass wire should not be used because the data being transmitted will be corrupted.