Toyota Corolla Cross: No Answer-Back

DESCRIPTION

In some cases, wireless door lock control functions are normal but the hazard warning light and wireless door lock buzzer answer-back function do not operate. In such cases, hazard warning light and wireless door lock buzzer signal outputs from the main body ECU (multiplex network body ECU) may be malfunctioning.

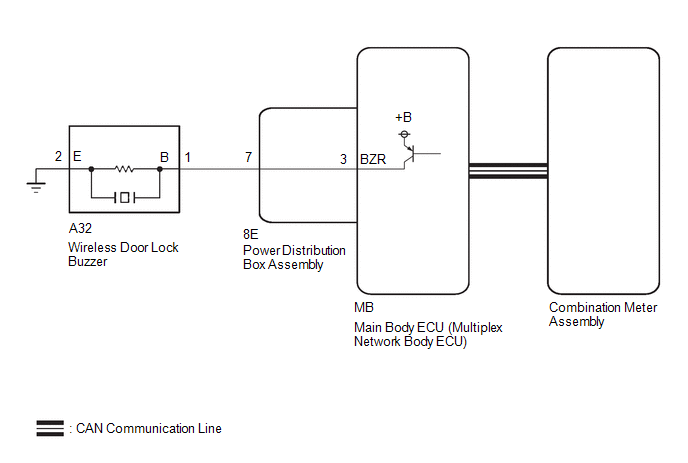

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The wireless door lock control system uses the CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the wireless door lock control system after confirming that the communication system is functioning properly.

Click here

.gif)

- If the main body ECU (multiplex network body ECU) is replaced, refer to the Registration.

- for HEV Model: Click here

.gif)

- for Gasoline Model: Click here

.gif)

- for HEV Model: Click here

- Before performing the inspection, check that DTC B124296 (wireless door lock control) is not output.

Click here

.gif)

PROCEDURE

|

1. | CHECK CUSTOMIZE SETTING USING GTS |

(a) Select the setting by referring to the table below.

Wireless Door Lock|

Tester Display | Description |

Default | Setting |

ECU |

|---|---|---|---|---|

| Wireless Buzzer Response Function |

Function that enables/disables the wireless door lock buzzer response |

Enable | $00:Disable,$01:Enable |

Main body ECU (Multiplex network body ECU) |

|

Hazard Answer Back Function |

Function that flashes the hazard warning lights once when the doors are locked by wireless operation and twice when the doors are unlocked by wireless operation |

Enable | $00:Disable,$01:Enable |

Main body ECU (Multiplex network body ECU) |

|

Wireless Buzzer Volume Setting |

Function that adjusts the wireless door lock buzzer volume |

Level5 | $00:Level7(MAX),$01:Level6,$02:Level5,$03:Level4,$04:Level3,$05:Level2,$06:Level1,$07:Level0(MIN) |

Main body ECU (Multiplex network body ECU) |

|

Result | Proceed to |

|---|---|

|

All settings are Enable and other than Level0 |

A |

| A setting is Disable or Level0 |

B |

| B |

.gif) | PERFORM CUSTOMIZE FUNCTION |

|

| 2. |

CHECK WIRELESS DOOR LOCK CONTROL FUNCTIONS |

(a) Check the wireless door lock control function using the electrical key transmitter sub-assembly.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Wireless door lock/unlock operates properly |

A |

| Wireless door lock/unlock does not operate properly |

B |

| B |

.gif) | GO TO PROBLEM SYMPTOMS TABLE |

|

| 3. |

READ VALUE USING GTS (DOOR LOCK POSITION SWITCH STATUS) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Main Body > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

FR Door Lock Position Switch Status |

Front door RH unlock detection switch signal |

Lock or Unlock | Lock: Front door RH locked Unlock: Front door RH unlocked |

- |

| FL Door Lock Position Switch Status |

Front door LH unlock detection switch signal |

Lock or Unlock | Lock: Front door LH locked Unlock: Front door LH unlocked |

- |

| RR Door Lock Position Switch Status |

Rear door RH unlock detection switch signal |

Lock or Unlock | Lock: Rear door RH locked Unlock: Rear door RH unlocked |

- |

| RL Door Lock Position Switch Status |

Rear door LH unlock detection switch signal |

Lock or Unlock | Lock: Rear door LH locked Unlock: Rear door LH unlocked |

- |

|

Tester Display |

|---|

| FR Door Lock Position Switch Status |

|

FL Door Lock Position Switch Status |

|

RR Door Lock Position Switch Status |

|

RL Door Lock Position Switch Status |

OK:

The GTS display changes correctly in response to the lock/unlock operation.

| NG | .gif) | GO TO LIGHTING SYSTEM (Proceed to Door Unlock Detection Switch Circuit) |

|

| 4. |

CHECK WIRELESS ANSWER-BACK OPERATION |

(a) Check the wireless answer-back operation using the electrical key transmitter sub-assembly.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Only wireless door lock buzzer answer-back does not occur. |

A |

| Only hazard warning light answer-back does not occur. |

B |

| B |

.gif) | GO TO STEP 9 |

|

| 5. |

PERFORM ACTIVE TEST USING GTS (WIRELESS BUZZER) |

(a) Perform the Active Test according to the display on the GTS.

Body Electrical > Main Body > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Wireless Buzzer | Wireless door lock buzzer |

OFF/ON | - |

|

Tester Display |

|---|

| Wireless Buzzer |

OK:

Wireless door lock buzzer sounds

| OK | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 6. |

CHECK MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

(a) Disconnect the A32 wireless door lock buzzer connector.

(b) Perform the Active Test according to the display on the GTS.

Body Electrical > Main Body > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Wireless Buzzer | Wireless door lock buzzer |

OFF/ON | - |

|

Tester Display |

|---|

| Wireless Buzzer |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A32-1 (B) - A32-2 (E) |

Active Test Wireless Buzzer is OFF |

Below 1 V |

|

Active Test Wireless Buzzer is ON |

Pulse generation (frequency: 2 kHz, high voltage: 11 to 14 V, low voltage: below 1 V) |

| OK | .gif) | REPLACE WIRELESS DOOR LOCK BUZZER |

|

| 7. |

CHECK HARNESS AND CONNECTOR (WIRELESS DOOR LOCK BUZZER - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) AND BODY GROUND)) |

(a) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

Click here .gif)

(b) Reconnect the power distribution box assembly connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A32-1 (B) - MB-3 (BZR) |

Always | Below 1 Ω |

|

A32-2 (E) - Body ground |

Always | Below 1 Ω |

|

A32-1 (B) or MB-3 (BZR) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 8. |

CHECK HARNESS AND CONNECTOR (WIRELESS DOOR LOCK BUZZER - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the 8E power distribution box assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A32-1 (B) - 8E-7 | Always |

Below 1 Ω |

|

A32-1 (B) or 8E-7 - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE POWER DISTRIBUTION BOX ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 9. |

CHECK HAZARD WARNING LIGHTS OPERATION |

(a) Check that the hazard warning lights blink when the hazard warning signal switch is pressed.

OK:

Hazard warning lights blink.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (w/ AFS) | B |

|

NG (w/o AFS) | C |

| A |

.gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| B |

.gif) | GO TO LIGHTING SYSTEM (Proceed to Hazard Warning Switch Circuit) |

| C |

.gif) | GO TO LIGHTING SYSTEM (Proceed to Hazard Warning Switch Circuit) |

.gif)