Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

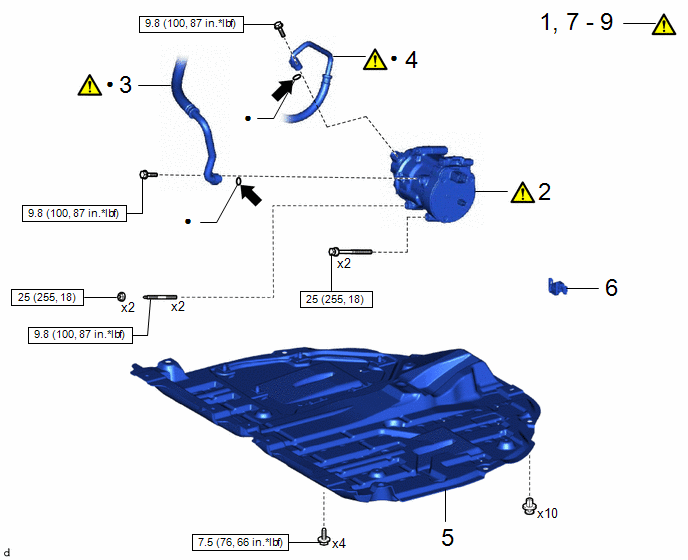

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | ADJUST COMPRESSOR OIL |

- |

|

- | - |

|

2 | COMPRESSOR WITH MOTOR ASSEMBLY |

88370 |

|

- | - |

|

3 | SUCTION HOSE SUB-ASSEMBLY |

88704 |

|

- | - |

|

4 | DISCHARGE HOSE SUB-ASSEMBLY |

88703 |

|

- | - |

|

5 | NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 | - |

- | - |

|

6 | SERVICE PLUG GRIP |

G3834 | - |

- | - |

|

7 | CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

- |

|

- | - |

|

8 | WARM UP COMPRESSOR |

- |

|

- | - |

|

9 | INSPECT FOR REFRIGERANT LEAK |

- |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

Compressor oil ND-OIL 11 or equivalent |

- | - |

PROCEDURE

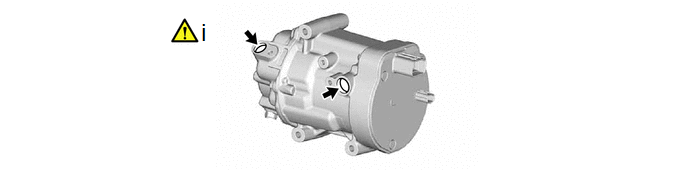

1. ADJUST COMPRESSOR OIL

(a) When replacing the compressor with motor assembly with a new one:

(1) Gradually discharge the inert gas from the service valve, and drain the following amount of oil from the new compressor with motor assembly before installation.

Standard:

(Oil capacity inside the new compressor with motor assembly: 110 to 125 cc (3.73 to 4.22 fl. oz)) - (Remaining oil amount in the removed compressor with motor assembly) = (Oil amount to be removed from the new compressor)

NOTICE:

- If a new compressor with motor assembly is installed without removing some oil, there will be too much oil in the system due to the oil remaining in the pipes of the vehicle. Excessive oil in the system prevents heat exchange in the refrigeration cycle and causes ineffective cooling.

- If the amount of oil remaining in the old compressor with motor assembly is too small, check the air conditioning system for oil leaks.

- Be sure to use ND-OIL 11 or equivalent compressor oil. If any compressor oil other than ND-OIL 11 is used, compressor with motor assembly insulation performance may decrease, resulting in leakage of electric power.

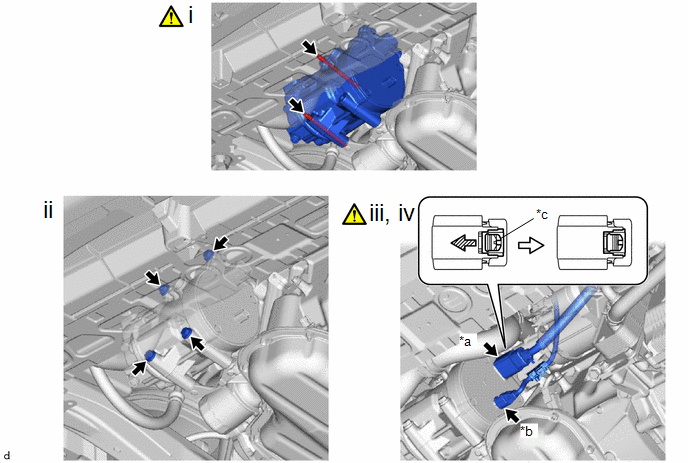

2. INSTALL COMPRESSOR WITH MOTOR ASSEMBLY

|

*a | Connector (A) |

*b | Connector (B) |

|

*c | Green-colored Lock |

- | - |

.png) |

Slide | - |

- |

(1) Using an E8 "TORX" socket wrench, install the compressor with motor assembly with the 2 stud bolts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

(2) Install the 2 bolts and 2 nuts.

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(3) Connect the connector (B).

(4) Remove the insulating tape from the connector (A), connect the connector (A) and slide the green-colored lock as shown in the illustration to securely lock it.

CAUTION:

Make sure to wear insulated gloves.

NOTICE:

Make sure that the connector is connected securely.

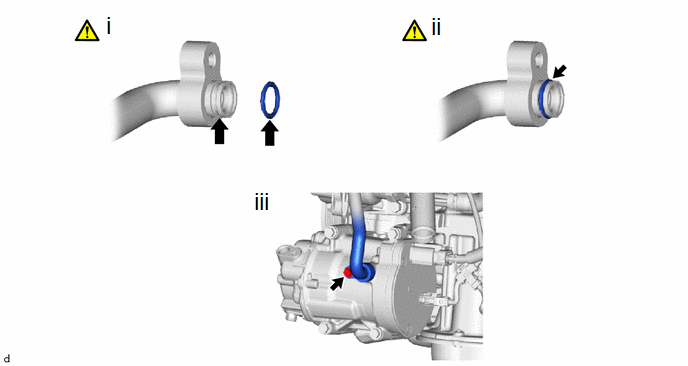

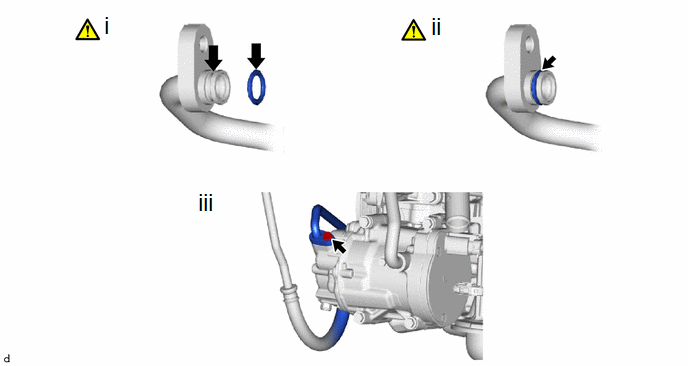

3. CONNECT SUCTION HOSE SUB-ASSEMBLY

(1) Remove the vinyl tape from the suction hose sub-assembly and sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(2) Install the O-ring to the suction hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Connect the suction hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

4. CONNECT DISCHARGE HOSE SUB-ASSEMBLY

(1) Remove the vinyl tape from the discharge hose sub-assembly and sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(2) Install the O-ring to the discharge hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Connect the discharge hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

5. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

6. INSTALL SERVICE PLUG GRIP

Click here

.gif)

7. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

Click here .gif)

8. WARM UP COMPRESSOR

Click here .gif)

9. INSPECT FOR REFRIGERANT LEAK

Click here .gif)