Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | TEMPORARILY INSTALL AIR CONDITIONER UNIT ASSEMBLY |

- |

|

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

2 | INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONER UNIT ASSEMBLY |

- |

|

- | - |

|

3 | NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY |

55307C |

|

- | - |

|

4 | NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY |

55306A |

|

- | - |

|

5 | INSTALL AIR CONDITIONER UNIT ASSEMBLY |

- |

|

- | - |

|

6 | INSTRUMENT PANEL WIRE |

- |

|

- | - |

|

7 | TELEPHONE TRANSCEIVER WITH BRACKET |

- | - |

- | - |

|

8 | DRAIN COOLER HOSE |

88539J |

|

- | - |

|

*A | w/ Telematics Transceiver |

*B | except Cold Area Specification Vehicles |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

9 | NO. 3 DASH PANEL INSULATOR PAD |

55215D |

|

- | - |

|

10 | FRONT FLOOR CARPET ASSEMBLY |

58510D | - |

- | - |

|

*A | except Cold Area Specification Vehicles |

- | - |

|

● | Non-reusable part |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

11 | NO. 1 REAR AIR DUCT |

87212 | - |

- | - |

|

12 | NO. 2 REAR AIR DUCT |

87213D | - |

- | - |

|

13 | NO. 4 REAR AIR DUCT |

87212H | - |

- | - |

|

14 | FRONT FLOOR CARPET ASSEMBLY |

58510D | - |

- | - |

|

15 | NO. 3 REAR AIR DUCT |

87212G | - |

- | - |

|

16 | NO. 5 REAR AIR DUCT |

87217C | - |

- | - |

|

17 | FUEL LID LOCK OPEN LEVER SUB-ASSEMBLY |

77306 | - |

- | - |

|

*A | for Cold Area Specification Vehicles |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

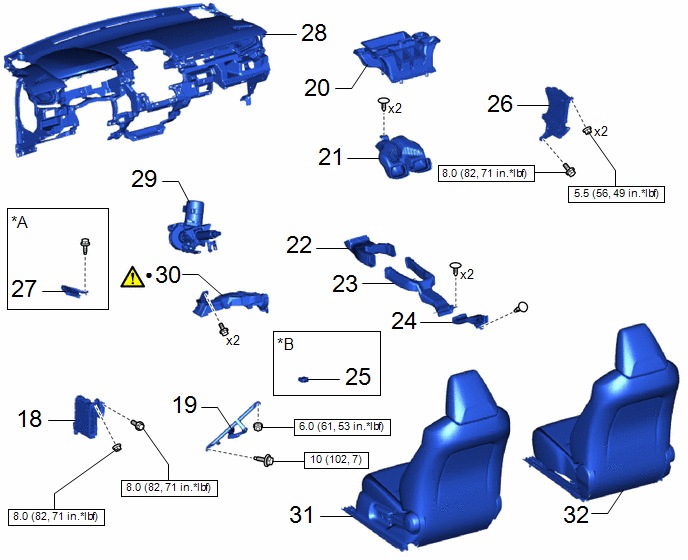

18 | INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU |

- | - |

- | - |

|

19 | NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY |

55308B | - |

- | - |

|

20 | LOWER DEFROSTER NOZZLE ASSEMBLY |

55990B | - |

- | - |

|

21 | CENTER HEATER TO REGISTER DUCT SUB-ASSEMBLY |

55086A | - |

- | - |

|

22 | NO. 1 CONSOLE BOX DUCT |

58861B | - |

- | - |

|

23 | NO. 2 CONSOLE BOX DUCT |

58862B | - |

- | - |

|

24 | NO. 3 CONSOLE BOX DUCT |

58863A | - |

- | - |

|

25 | COOLER THERMISTOR (ROOM TEMPERATURE SENSOR) |

88625Q | - |

- | - |

|

26 | CONNECTOR HOLDER |

82666 | - |

- | - |

|

27 | CLEARANCE WARNING ECU ASSEMBLY |

89340A | - |

- | - |

|

28 | INSTRUMENT PANEL SAFETY PAD ASSEMBLY |

- | - |

- | - |

|

29 | STEERING COLUMN ASSEMBLY |

- | - |

- | - |

|

30 | NO. 1 AIR DUCT |

87211 |

|

- | - |

|

31 | FRONT SEAT ASSEMBLY LH |

- | - |

- | - |

|

32 | FRONT SEAT ASSEMBLY RH |

- | - |

- | - |

|

*A | w/ Parking Support Brake System |

*B | for Automatic Air Conditioning System |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

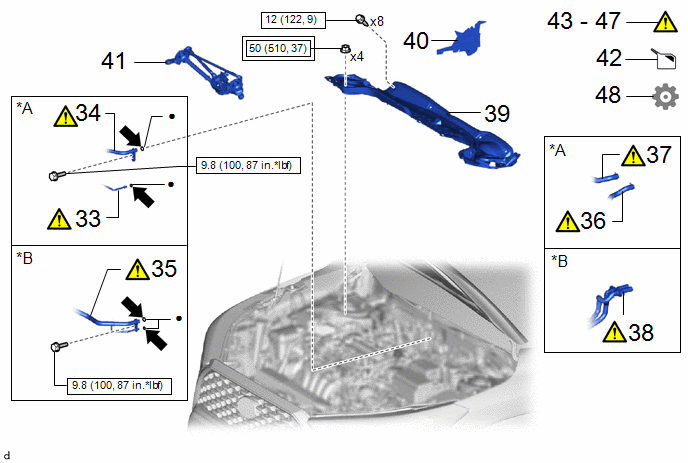

33 | AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY |

88710E |

|

- | - |

|

34 | SUCTION PIPE SUB-ASSEMBLY |

88707 |

|

- | - |

|

35 | NO. 2 AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY |

88710G |

|

- | - |

|

36 | INLET HEATER WATER HOSE |

- |

|

- | - |

|

37 | OUTLET HEATER WATER HOSE |

- |

|

- | - |

|

38 | WATER HOSE SUB-ASSEMBLY |

- |

|

- | - |

|

39 | OUTER COWL TOP PANEL SUB-ASSEMBLY |

55701J | - |

- | - |

|

40 | NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL |

55737B | - |

- | - |

|

41 | WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

- | - |

- | - |

|

42 | ADD ENGINE COOLANT |

- | - |

|

- |

| 43 |

INSPECT FOR COOLANT LEAK |

- |

|

- | - |

|

44 | CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

- |

|

- | - |

|

45 | WARM UP ENGINE |

- |

|

- | - |

|

46 | WARM UP COMPRESSOR |

- |

|

- | - |

|

47 | INSPECT FOR REFRIGERANT LEAK |

- |

|

- | - |

|

48 | INITIALIZATION SERVO MOTOR |

- | - |

- |

|

|

*A | for Gasoline Model |

*B | for HEV Model |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

.png) |

for Gasoline Model: Compressor oil ND-OIL 12 or equivalent for HEV Model: Compressor oil ND-OIL 11 or equivalent |

PROCEDURE

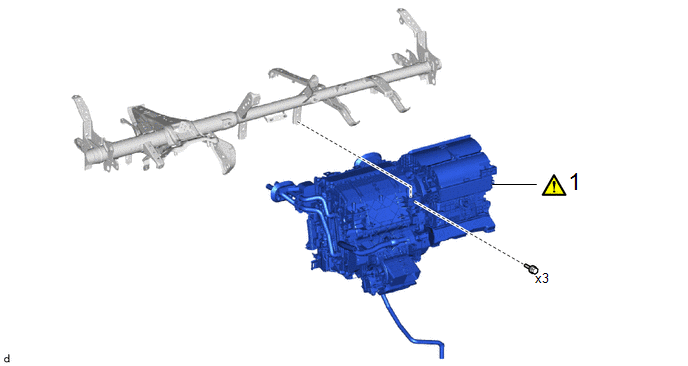

1. TEMPORARILY INSTALL AIR CONDITIONER UNIT ASSEMBLY

(1) Temporarily install the air conditioner unit assembly to the instrument panel reinforcement assembly with the 3 bolts.

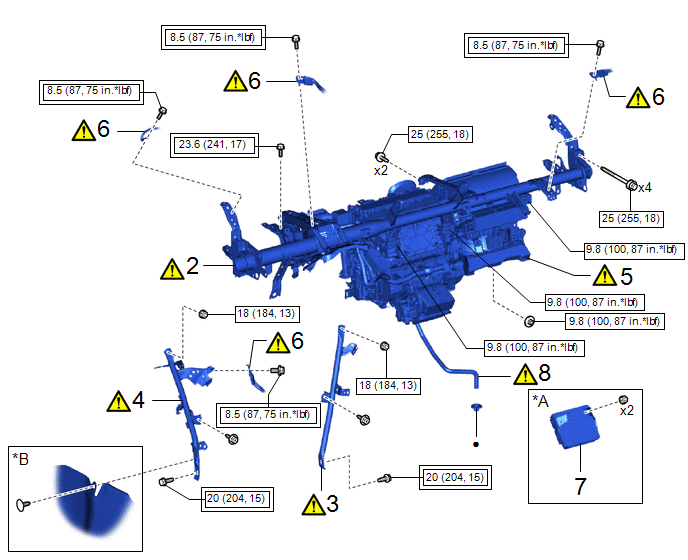

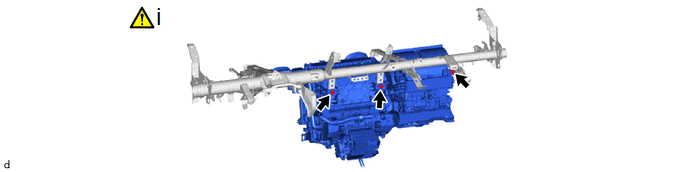

2. INSTALL INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONER UNIT ASSEMBLY

.png) |

NOTICE:

|

|

*a | Bolt (A) |

*b | Bolt (B) |

.png) |

Install in this Direction |

- | - |

(1) Connect the 2 connectors.

(2) Engage the hooks to install the instrument panel reinforcement assembly with air conditioner unit assembly as shown in the illustration.

(3) Install the 6 bolts (A).

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(4) Install the bolt (B).

Torque:

23.6 N·m {241 kgf·cm, 17 ft·lbf}

(5) Temporarily install the nut.

NOTICE:

Do not fully tighten the nut.

3. INSTALL NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

.png) |

Install in this Direction |

- | - |

(1) Install the No. 2 instrument panel brace sub-assembly with the bolt and nut.

Torque:

Bolt :

20 N·m {204 kgf·cm, 15 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

(2) Temporarily install the screw.

NOTICE:

Do not fully tighten the screw.

(3) Install the front floor mat to its original position as shown in the illustration.

4. INSTALL NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

|

*A | except Cold Area Specification Vehicles |

- | - |

.png) |

Install in this Direction |

- | - |

(1) Install the No. 1 instrument panel brace sub-assembly with the bolt and nut.

Torque:

Bolt :

20 N·m {204 kgf·cm, 15 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

(2) Temporarily install the screw.

NOTICE:

Do not fully tighten the screw.

(3) Install the front floor mat to its original position as shown in the illustration.

(4) except Cold Area Specification Vehicles:

1. Install the clip.

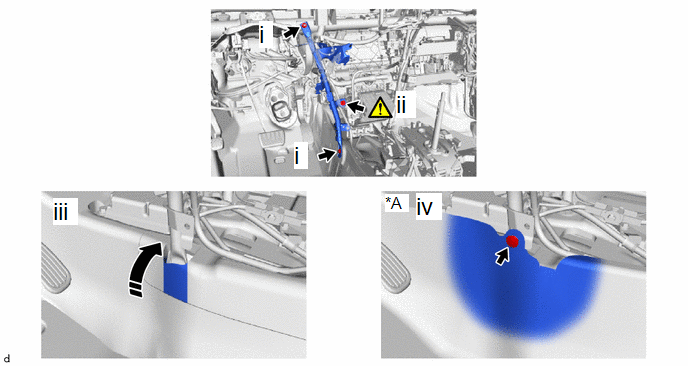

5. INSTALL AIR CONDITIONER UNIT ASSEMBLY

(1) Tighten the 3 bolts, 2 screws and nut to install the air conditioner unit assembly in the order shown in the illustration.

Torque:

Bolt :

9.8 N·m {100 kgf·cm, 87 in·lbf}

Nut :

9.8 N·m {100 kgf·cm, 87 in·lbf}

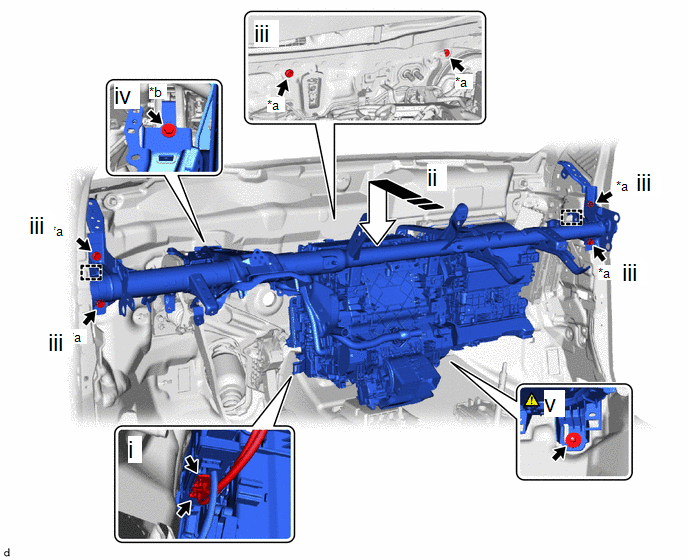

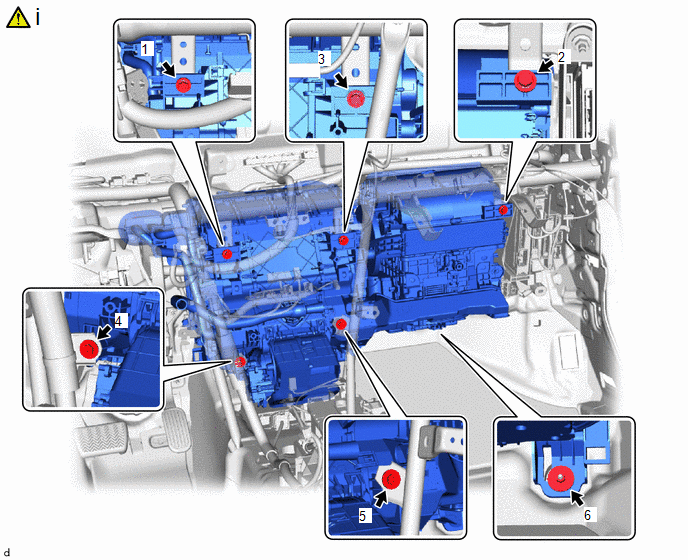

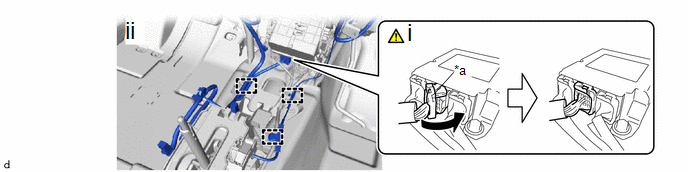

6. CONNECT INSTRUMENT PANEL WIRE

HINT:

The illustrations are representative examples, and details may differ.

|

*a | Clamp |

*b | Guide |

(1) Engage the guides and clamps to connect the instrument panel wire.

(2) Install the 4 bolts.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

|

*a | Lock Lever |

- | - |

.png) |

Down | - |

- |

(1) Connect the connector and pull down the lock lever as shown in the illustration.

NOTICE:

When connecting any airbag connector, take care not to damage the airbag wire harness.

(2) Engage the clamps.

7. INSTALL TELEPHONE TRANSCEIVER WITH BRACKET (w/ Telematics Transceiver)

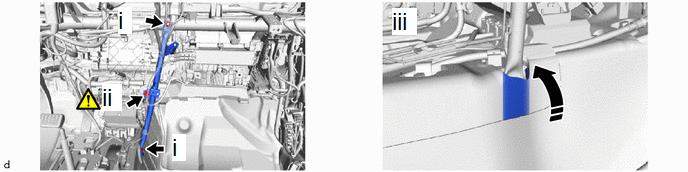

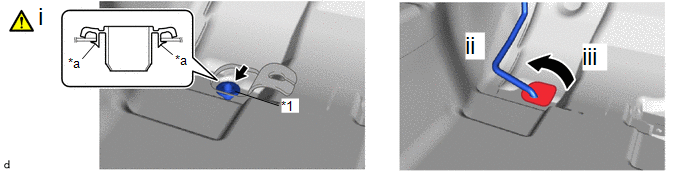

8. CONNECT DRAIN COOLER HOSE

|

*1 | Cooler Unit Drain Hose Grommet |

- | - |

|

*a | Lip |

- | - |

(1) Install a new cooler unit drain hose grommet.

NOTICE:

- If the drain cooler hose is disconnected from the cooler unit drain hose grommet, make sure to replace the cooler unit drain hose grommet with a new one. Failure to do so may lead to water ingress.

- Make sure that the entire lip of the cooler unit drain hose grommet is securely engaged to the vehicle body.

(2) Connect the drain cooler hose.

(3) Install the front floor mat to its original position as shown in the illustration.

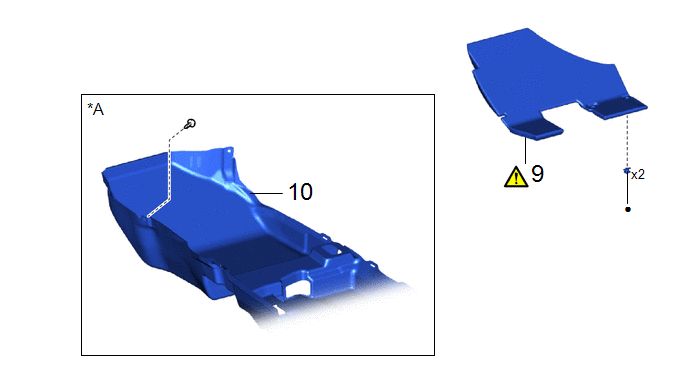

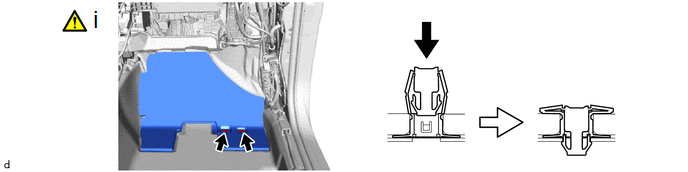

9. INSTALL NO. 3 DASH PANEL INSULATOR PAD

.png) |

Push | - |

- |

(1) Install the No. 3 dash panel insulator pad with 2 new clips as shown in the illustration.

10. CONNECT FRONT FLOOR CARPET ASSEMBLY (except Cold Area Specification Vehicles)

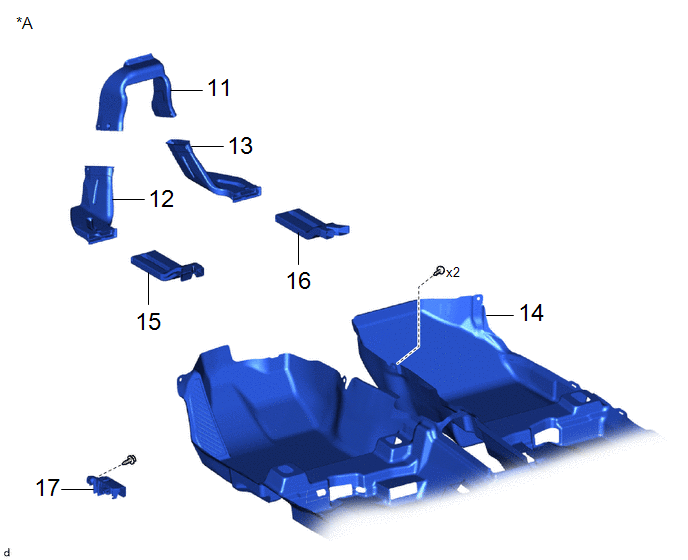

11. INSTALL NO. 1 REAR AIR DUCT (for Cold Area Specification Vehicles)

12. INSTALL NO. 2 REAR AIR DUCT (for Cold Area Specification Vehicles)

13. INSTALL NO. 4 REAR AIR DUCT (for Cold Area Specification Vehicles)

14. INSTALL FRONT FLOOR CARPET ASSEMBLY (for Cold Area Specification Vehicles)

15. INSTALL NO. 3 REAR AIR DUCT (for Cold Area Specification Vehicles)

16. INSTALL NO. 5 REAR AIR DUCT (for Cold Area Specification Vehicles)

17. INSTALL FUEL LID LOCK OPEN LEVER SUB-ASSEMBLY (for Cold Area Specification Vehicles)

18. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

19. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

Torque:

Bolt :

10 N·m {102 kgf·cm, 7 ft·lbf}

Nut :

6.0 N·m {61 kgf·cm, 53 in·lbf}

20. INSTALL LOWER DEFROSTER NOZZLE ASSEMBLY

21. INSTALL CENTER HEATER TO REGISTER DUCT SUB-ASSEMBLY

22. INSTALL NO. 1 CONSOLE BOX DUCT

23. INSTALL NO. 2 CONSOLE BOX DUCT

24. INSTALL NO. 3 CONSOLE BOX DUCT

25. INSTALL COOLER THERMISTOR (ROOM TEMPERATURE SENSOR) (for Automatic Air Conditioning System)

26. INSTALL CONNECTOR HOLDER

27. INSTALL CLEARANCE WARNING ECU ASSEMBLY (w/ Parking Support Brake System)

28. INSTALL INSTRUMENT PANEL SAFETY PAD ASSEMBLY

Click here

.gif)

29. INSTALL STEERING COLUMN ASSEMBLY

Click here .gif)

30. INSTALL NO. 1 AIR DUCT

.png) |

NOTICE: If the fitting part of the No. 1 air duct has been cracked or deformed during removal, make sure to replace the air duct with a new one. Failure to do so may cause the No. 1 air duct to fall off or noise to occur. |

31. INSTALL FRONT SEAT ASSEMBLY LH

- for Manual Seat:

Click here

.gif)

- for Power Seat:

Click here

.gif)

32. INSTALL FRONT SEAT ASSEMBLY RH

33. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (for Gasoline Model)

(1) Remove the vinyl tape from the air conditioning tube and accessory assembly and sufficiently apply compressor oil to a new O-ring and the fitting surface of the air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 12 or equivalent

(2) Install the O-ring to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Connect the air conditioning tube and accessory assembly.

34. CONNECT SUCTION PIPE SUB-ASSEMBLY (for Gasoline Model)

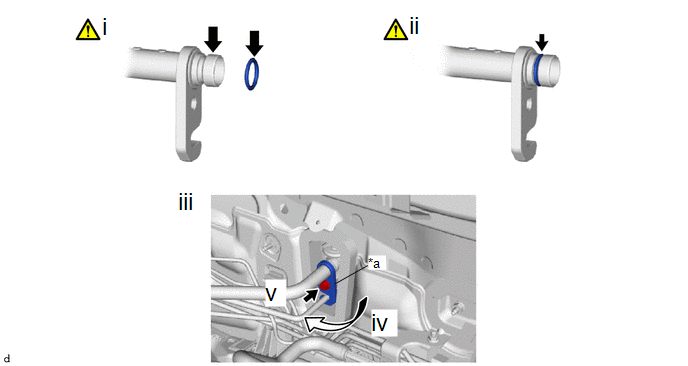

|

*a | Hook Connector |

- | - |

(1) Remove the vinyl tape from the suction pipe sub-assembly and sufficiently apply compressor oil to a new O-ring and the fitting surface of the suction pipe sub-assembly.

Compressor Oil:

ND-OIL 12 or equivalent

(2) Install the O-ring to the suction pipe sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Connect the suction pipe sub-assembly.

(4) Rotate the hook connector as shown in the illustration.

(5) Install the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

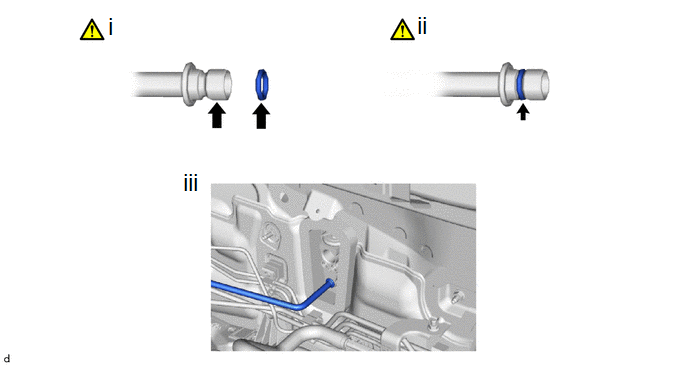

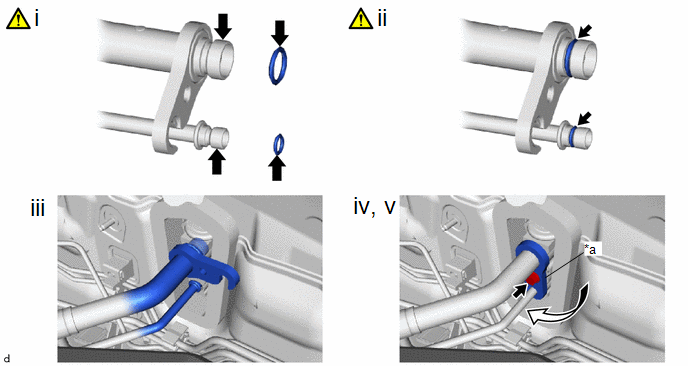

35. CONNECT NO. 2 AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (for HEV Model)

|

*a | Hook Connector |

- | - |

(1) Remove the vinyl tape from the No. 2 air conditioning tube and accessory assembly and sufficiently apply compressor oil to 2 new O-rings and the fitting surface of the No. 2 air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(2) Install the 2 O-rings to the No. 2 air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Connect the No. 2 air conditioning tube and accessory assembly.

(4) Rotate the hook connector as shown in the illustration.

(5) Install the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

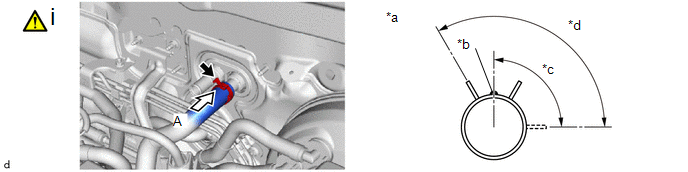

36. CONNECT INLET HEATER WATER HOSE (for Gasoline Model)

|

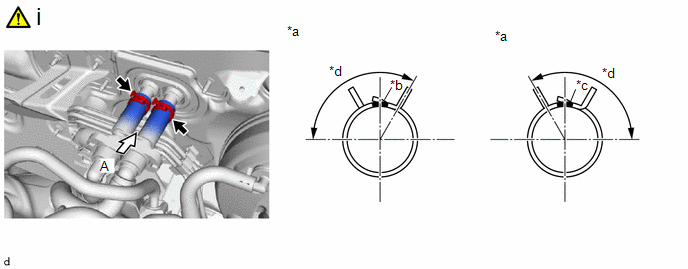

*a | View A |

*b | Marking (White) |

|

*c | Clip Installation Angle (90°) |

*d | Clip Installation Angle (120°) |

(1) Connect the inlet heater water hose with the marking facing up and engage the clip within the area shown in the illustration.

NOTICE:

Do not apply excessive force to the inlet heater water hose.

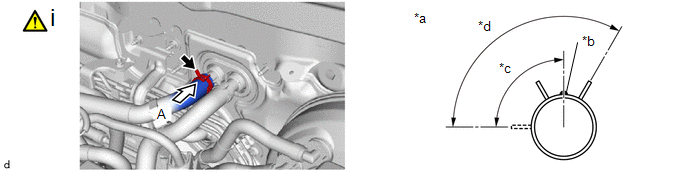

37. CONNECT OUTLET HEATER WATER HOSE (for Gasoline Model)

|

*a | View A |

*b | Marking (Yellow) |

|

*c | Clip Installation Angle (90°) |

*d | Clip Installation Angle (120°) |

(1) Connect the outlet heater water hose with the marking facing up and engage the clip within the area shown in the illustration.

NOTICE:

Do not apply excessive force to the outlet heater water hose.

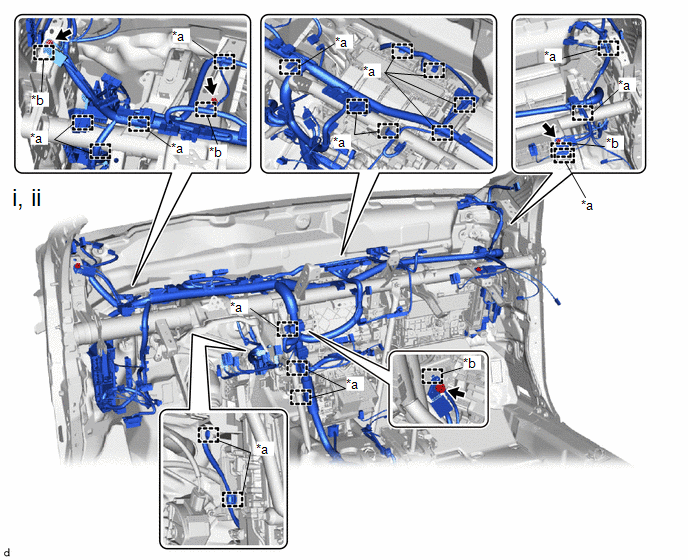

38. CONNECT WATER HOSE SUB-ASSEMBLY (for HEV Model)

|

*a | View A |

*b | Marking (Purple) |

|

*c | Marking (White) |

*d | Clip Installation Angle (120°) |

(1) Connect the water hose sub-assembly with the marking facing up and engage the clips within the area shown in the illustration.

NOTICE:

Do not apply excessive force to the water hose sub-assembly.

39. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

40. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

41. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here

.gif)

42. ADD ENGINE COOLANT

- for M20A-FKS:

Click here

.gif)

- for M20A-FXS:

Click here

.gif)

43. INSPECT FOR COOLANT LEAK

- for M20A-FKS:

Click here

.gif)

- for M20A-FXS:

Click here

.gif)

44. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

Click here

.gif)

45. WARM UP ENGINE (for Gasoline Model)

Click here .gif)

46. WARM UP COMPRESSOR (for HEV Model)

Click here .gif)

47. INSPECT FOR REFRIGERANT LEAK

Click here .gif)

48. INITIALIZATION SERVO MOTOR

- for Gasoline Model with Manual Air Conditioning System:

Click here

.gif)

- for Gasoline Model with Automatic Air Conditioning System:

Click here

.gif)

- for HEV Model:

Click here

.gif)