Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

CAUTION / NOTICE / HINT

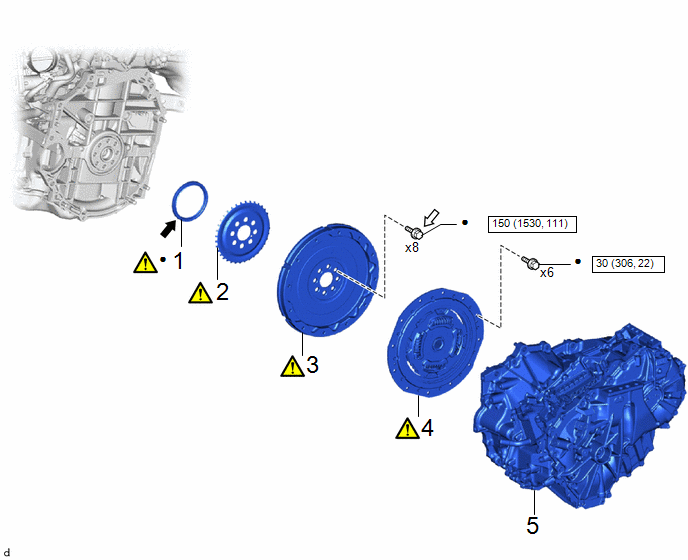

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | REAR ENGINE OIL SEAL |

11401L |

|

- | - |

|

2 | NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

19315 |

|

- | - |

|

3 | FLYWHEEL SUB-ASSEMBLY |

13405 |

|

- | - |

|

4 | TRANSMISSION INPUT DAMPER ASSEMBLY |

31270 |

|

- | - |

|

5 | HYBRID VEHICLE TRANSAXLE ASSEMBLY |

30900 | - |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

MP grease |

.png) |

Adhesive 1324 |

|

★ | Precoated part |

- | - |

PROCEDURE

1. INSTALL REAR ENGINE OIL SEAL

.png)

|

*a | -0.9 to 1.1 mm |

- | - |

(1) Apply MP grease to the lip of a new rear engine oil seal.

NOTICE:

- Keep the lip free from foreign matter.

- Do not allow MP grease to contact the dust seal.

(2) Using SST and a hammer, tap in the rear engine oil seal.

SST: 09223-15030

SST: 09950-70010

09951-07150

Standard Depth:

-0.9 to 1.1 mm (-0.0354 to 0.0433 in.) (From the edge of the cylinder block sub-assembly and stiffening crankcase assembly)

NOTICE:

Do not tap in the rear engine oil seal at an angle.

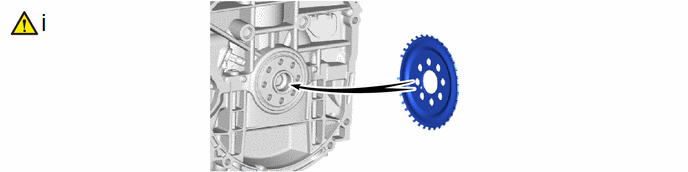

2. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE

(1) Install the No. 1 crankshaft position sensor plate.

HINT:

Align the pin hole of the No. 1 crankshaft position sensor plate with the pin of the crankshaft.

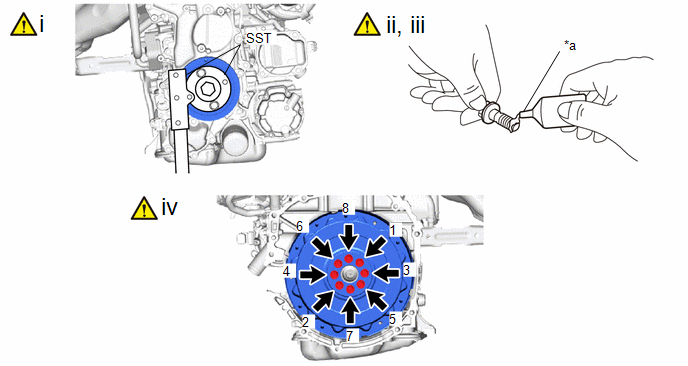

3. INSTALL FLYWHEEL SUB-ASSEMBLY

|

*a | Adhesive |

- | - |

(1) Using SST, hold the crankshaft pulley assembly.

SST: 09213-54015

SST: 09330-00021

(2) Clean the bolts and bolt holes.

(3) Apply adhesive to 2 or 3 threads at the end of 8 new bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

(4) Install the flywheel sub-assembly with the 8 bolts. Uniformly tighten the 8 bolts in the order shown in the illustration.

Torque:

150 N·m {1530 kgf·cm, 111 ft·lbf}

NOTICE:

Do not start the engine for at least 1 hour after installing the flywheel sub-assembly.

4. INSTALL TRANSMISSION INPUT DAMPER ASSEMBLY

(1) Using SST, hold the crankshaft pulley assembly.

SST: 09213-54015

SST: 09330-00021

(2) Install the transmission input damper assembly to the flywheel sub-assembly with the 6 bolts. Uniformly tighten the 6 bolts in the order shown in the illustration.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

NOTICE:

- Make sure that there are no oil on the transmission input damper assembly and flywheel sub-assembly.

- Make sure to install the transmission input damper assembly in the correct direction.

- Do not allow grease to contact the splines of the transmission input damper assembly and the input shaft.

5. INSTALL HYBRID VEHICLE TRANSAXLE ASSEMBLY

Click here

.gif)