Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

REAR DRIVE SHAFT INBOARD JOINT SHAFT SNAP RING |

42360M |

|

- |

- |

|

2 |

REAR DRIVE SHAFT ASSEMBLY |

42340B |

|

- |

- |

|

*1 |

REAR DRIVE SHAFT OIL SEAL |

- |

- |

|

● |

Non-reusable part |

.png) |

MP Grease |

.png) |

Toyota Genuine Differential Gear Oil LT |

.png) |

Do not apply lubricants to the threaded parts |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

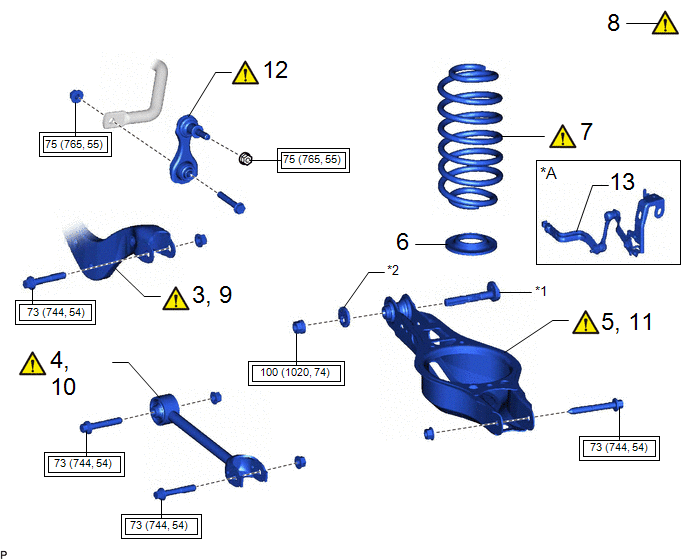

3 |

TEMPORARILY INSTALL REAR UPPER CONTROL ARM ASSEMBLY |

48790 |

|

- |

- |

|

4 |

TEMPORARILY INSTALL REAR NO. 1 SUSPENSION ARM ASSEMBLY |

48720A |

|

- |

- |

|

5 |

TEMPORARILY INSTALL REAR NO. 2 SUSPENSION ARM ASSEMBLY |

48740F |

|

- |

- |

|

6 |

REAR LOWER COIL SPRING INSULATOR |

48258C |

- |

- |

- |

|

7 |

REAR COIL SPRING |

48231B |

|

- |

- |

|

8 |

STABILIZE SUSPENSION |

- |

|

- |

- |

|

9 |

FULLY TIGHTEN REAR UPPER CONTROL ARM ASSEMBLY |

48790 |

|

- |

- |

|

10 |

FULLY TIGHTEN REAR NO. 1 SUSPENSION ARM ASSEMBLY |

48720A |

|

- |

- |

|

11 |

FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY |

48740F |

|

- |

- |

|

12 |

REAR STABILIZER LINK ASSEMBLY |

48840A |

|

- |

- |

|

13 |

REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH |

89408C |

- |

- |

- |

|

*A |

for LH Side with Height Control Sensor |

- |

- |

|

*1 |

REAR SUSPENSION TOE ADJUST CAM SUB-ASSEMBLY |

*2 |

NO. 2 CAMBER ADJUST CAM |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

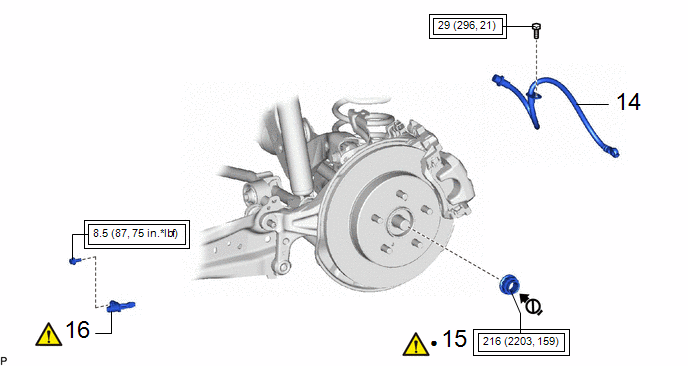

14 |

REAR FLEXIBLE HOSE |

47319F |

- |

- |

- |

|

15 |

REAR AXLE SHAFT NUT |

42312B |

|

- |

- |

|

16 |

REAR SKID CONTROL SENSOR |

89544E |

|

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

.png) |

Do not apply lubricants to the threaded parts |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

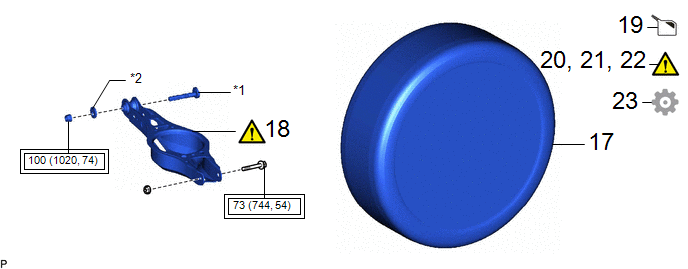

17 |

REAR WHEEL |

- |

- |

- |

- |

|

18 |

FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY |

48740F |

|

- |

- |

|

19 |

ADD DIFFERENTIAL OIL |

- |

- |

|

- |

|

20 |

INSPECT FOR DIFFERENTIAL OIL LEAK |

- |

|

- |

- |

|

21 |

INSPECT AND ADJUST REAR WHEEL ALIGNMENT |

- |

|

- |

- |

|

22 |

CHECK FOR SPEED SENSOR SIGNAL |

- |

|

- |

- |

|

23 |

PERFORM INITIALIZATION |

- |

- |

- |

|

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

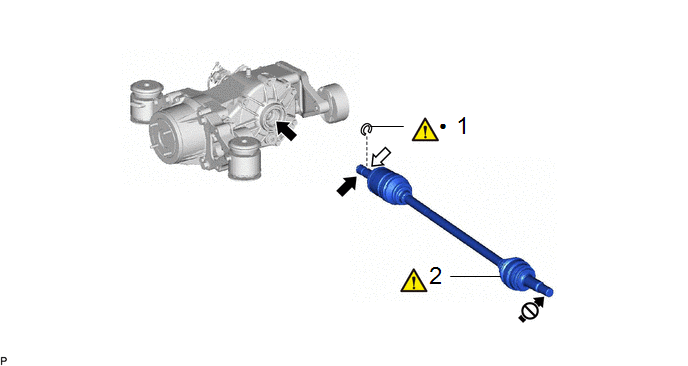

1. INSTALL REAR DRIVE SHAFT INBOARD JOINT SHAFT SNAP RING

.png) |

NOTICE: Face the end gap of the rear drive shaft inboard joint shaft snap ring downward. |

.png)

|

*a |

End Gap |

- |

- |

2. INSTALL REAR DRIVE SHAFT ASSEMBLY

|

*a |

Matchmark |

- |

- |

.png) |

MP Grease |

.png) |

Toyota Genuine Differential Gear Oil LT |

(1) Coat the lip of the rear drive shaft oil seal with MP grease.

HINT:

Apply a light coat of MP grease to the entire circumference of the rear drive shaft oil seal.

(2) Coat the rear drive shaft inboard joint shaft snap ring with MP grease.

(3) Coat the splines of the rear drive shaft inboard joint assembly with Toyota genuine differential gear oil LT.

(4) Align the inboard joint splines, and using a brass bar and a hammer, install the rear drive shaft assembly.

NOTICE:

- Face the end gap of the rear drive shaft inboard joint shaft snap ring downward.

- Do not damage the rear drive shaft oil seal.

- Do not damage the rear drive shaft inboard joint boot.

- Make sure to center the rear drive shaft assembly during installation to prevent damage to the rear drive shaft inboard joint shaft snap ring.

(5) Confirm whether the drive shaft is securely driven in by checking the reaction force and sound.

(6) Align the matchmarks and install the rear drive shaft assembly to the rear axle hub and bearing assembly.

NOTICE:

- Check that there is no foreign matter on the deflector or contact surfaces.

- Do not push the rear axle hub and bearing assembly towards the outside of the vehicle any further than necessary.

- Do not damage the rear drive shaft outboard joint boot.

- Do not deform the rear disc brake dust cover sub-assembly.

- Do not damage the deflector.

3. TEMPORARILY INSTALL REAR UPPER CONTROL ARM ASSEMBLY

.png)

(1) Temporarily install the rear upper control arm assembly to the rear axle carrier sub-assembly with the bolt and nut.

NOTICE:

Tighten the bolt with the nut secured.

4. TEMPORARILY INSTALL REAR NO. 1 SUSPENSION ARM ASSEMBLY

.png) |

Click here |

5. TEMPORARILY INSTALL REAR NO. 2 SUSPENSION ARM ASSEMBLY

.png) |

Click here |

6. INSTALL REAR LOWER COIL SPRING INSULATOR

7. INSTALL REAR COIL SPRING

.png) |

Click here |

8. STABILIZE SUSPENSION

.png) |

Click here |

9. FULLY TIGHTEN REAR UPPER CONTROL ARM ASSEMBLY

.png) |

NOTICE: Tighten the bolt with the nut secured. |

Torque:

73 N·m {744 kgf·cm, 54 ft·lbf}

10. FULLY TIGHTEN REAR NO. 1 SUSPENSION ARM ASSEMBLY

.png) |

Click here |

11. FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY

.png) |

Click here |

12. INSTALL REAR STABILIZER LINK ASSEMBLY

.png) |

Click here |

13. INSTALL REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH (for LH Side with Height Control Sensor)

Click here .gif)

14. INSTALL REAR FLEXIBLE HOSE

Click here .gif)

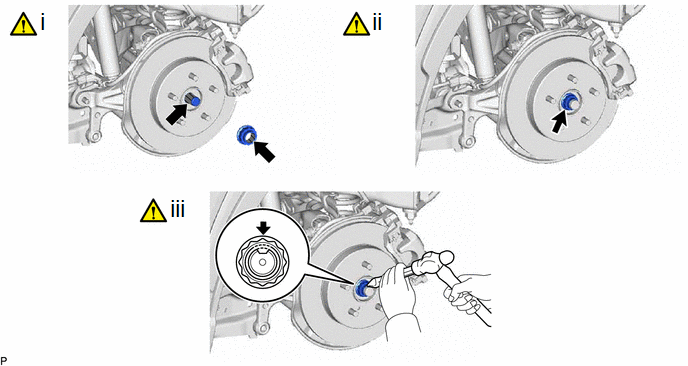

15. INSTALL REAR AXLE SHAFT NUT

(1) Clean the threaded parts on the rear drive shaft assembly and a new rear axle shaft nut using non-residue solvent.

NOTICE:

- Be sure to perform this work even when using a new rear drive shaft assembly.

- Keep the threaded parts free of oil and foreign matter.

(2) Using a 30 mm deep socket wrench, install the rear axle shaft nut while applying the brakes.

Torque:

216 N·m {2203 kgf·cm, 159 ft·lbf}

(3) Using a chisel and a hammer, stake the rear axle shaft nut.

16. INSTALL REAR SKID CONTROL SENSOR

.png) |

Click here |

17. INSTALL REAR WHEEL

Click here .gif)

18. FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY

.png) |

Click here |

19. ADD DIFFERENTIAL OIL

Click here .gif)

20. INSPECT FOR DIFFERENTIAL OIL LEAK

Click here .gif)

21. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

Click here .gif)

22. CHECK FOR SPEED SENSOR SIGNAL

Click here .gif)

23. PERFORM INITIALIZATION

|

Parking assist monitor system |

|

|

Automatic headlight beam level control system |

|