Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

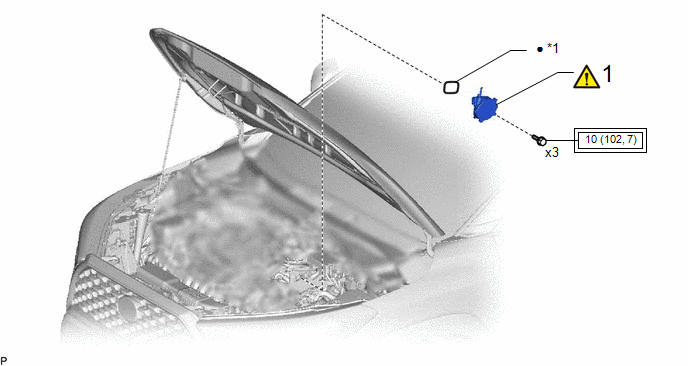

1 |

VACUUM PUMP ASSEMBLY |

29300 |

|

- |

- |

|

*1 |

NO. 1 VACUUM PUMP O-RING |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

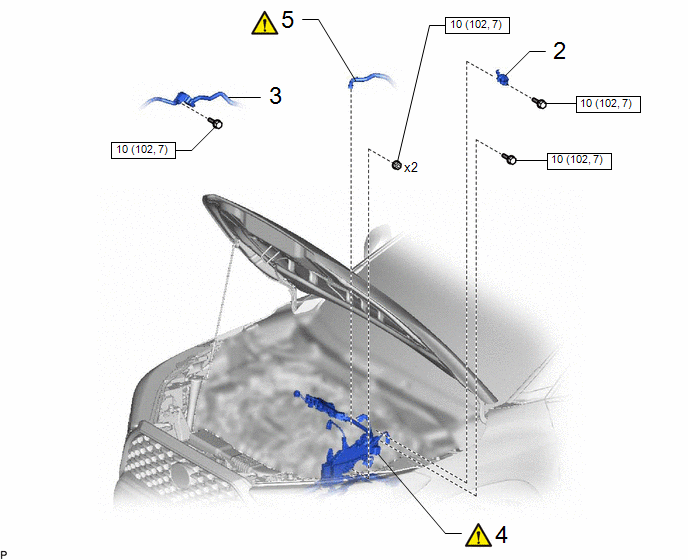

2 |

NO. 3 WATER HOSE CLAMP BRACKET |

16575F |

- |

- |

- |

|

3 |

VACUUM SURGE TANK |

25719 |

- |

- |

- |

|

4 |

ENGINE WIRE |

82121 |

|

- |

- |

|

5 |

NO. 1 VACUUM HOSE CONNECTOR |

44777 |

|

- |

- |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

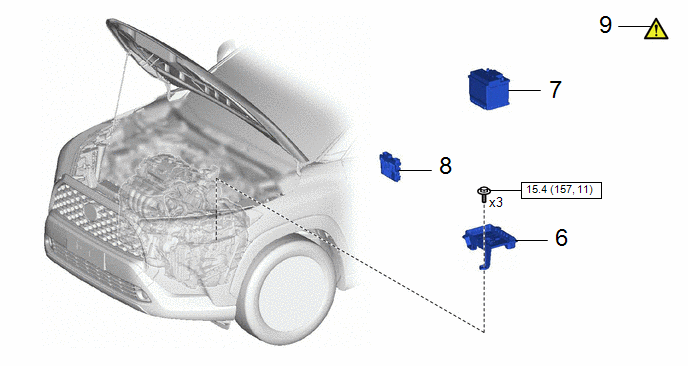

6 |

BATTERY CLAMP SUB-ASSEMBLY |

74404A |

- |

- |

- |

|

7 |

AUXILIARY BATTERY |

- |

- |

- |

- |

|

8 |

ECM |

89661 |

- |

- |

- |

|

9 |

INSPECT VACUUM PUMP OPERATION |

- |

|

- |

- |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

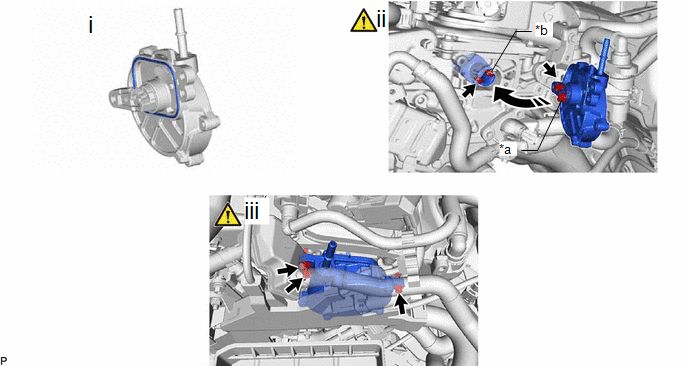

1. INSTALL VACUUM PUMP ASSEMBLY

(a) When reusing the vacuum pump assembly:

|

*a |

Coupling Teeth |

*b |

Groove |

.png) |

Install in this Direction |

- |

(1) Install a new No. 1 vacuum pump O-ring to the vacuum pump assembly.

(2) Install the vacuum pump assembly so that the coupling teeth of the vacuum pump assembly and groove of the camshaft are engaged.

NOTICE:

- Ensure that the vacuum pump assembly is installed securely.

- Be careful not to pinch the No. 1 vacuum pump O-ring.

(3) Using an 8 mm socket wrench, install the vacuum pump assembly with the 3 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

After installation, check that there are no gaps between the matching surfaces and that the vacuum pump assembly is not installed at an angle.

2. INSTALL NO. 3 WATER HOSE CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

3. INSTALL VACUUM SURGE TANK

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

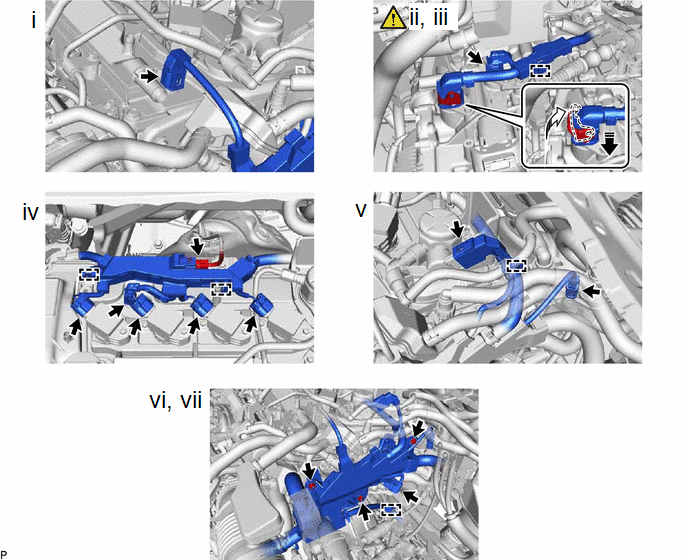

4. INSTALL ENGINE WIRE

.png) |

Connect the connector |

.png) |

Lock the lock lever |

(1) Connect the connector.

(2) Connect the connector and lock the lock lever.

(3) Connect the connector and engage the clamp.

(4) Connect the 6 connectors and engage the 2 clamps.

(5) Connect the 2 connectors and engage the clamp.

(6) Connect the connector and engage the clamp.

(7) Install the engine wire with the bolt and 2 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

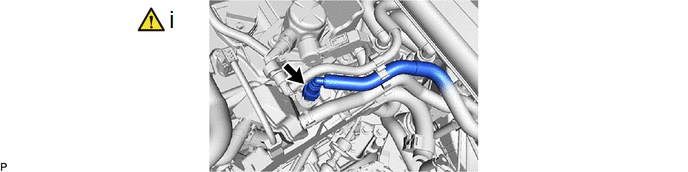

5. CONNECT NO. 1 VACUUM HOSE CONNECTOR

(1) Align the No. 1 vacuum hose connector with the vacuum pump assembly, and push them together until the No. 1 vacuum hose connector makes a "click" sound.

NOTICE:

- Check that there is no foreign matter on the connecting parts.

- After connecting the No. 1 vacuum hose connector, check that the vacuum pump assembly and No. 1 vacuum hose connector are securely connected by pulling on them.

6. INSTALL BATTERY CLAMP SUB-ASSEMBLY

Click here .gif)

7. INSTALL AUXILIARY BATTERY

Click here .gif)

.gif)

8. INSTALL ECM

Click here .gif)

.gif)

9. INSPECT VACUUM PUMP OPERATION

Click here .gif)