Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT SPIRAL CABLE SUB-ASSEMBLY

NOTICE:

- Do not remove the steering sensor from the spiral cable sub-assembly when inspecting the spiral cable sub-assembly.

- Remove the steering sensor from the spiral cable sub-assembly only when replacing the spiral cable sub-assembly.

(a) Visually check the spiral cable sub-assembly for defects.

(1) The defects are as follows:

- Scratches

- Small cracks

- Dents

- Chips

- Cracks or other damage to the connector

OK:

No defects are found.

If any of the defects is found, replace the spiral cable sub-assembly with a new one.

(b) Check the spiral cable sub-assembly.

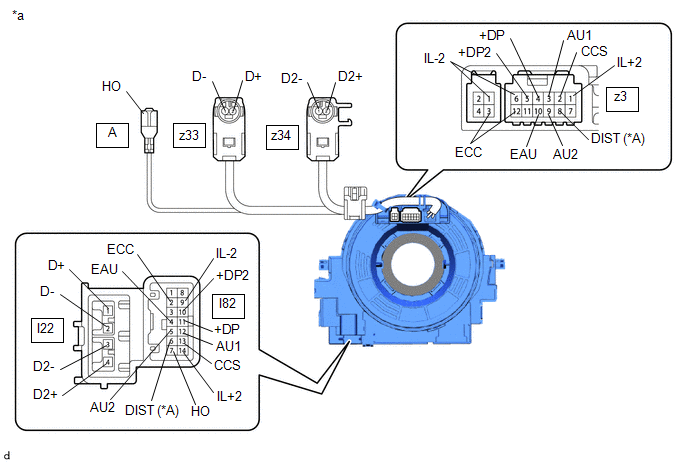

w/o Steering Heater

|

*A | w/ Lane Departure Alert System |

- | - |

|

*a | Component without harness connected (Spiral Cable Sub-assembly) |

- | - |

| Interlock |

- | - |

|

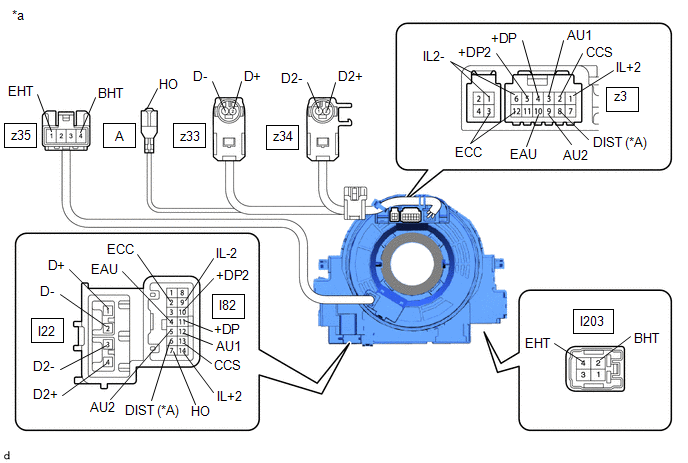

*A | w/ Lane Departure Alert System |

- | - |

|

*a | Component without harness connected (Spiral Cable Sub-assembly) |

- | - |

| Interlock |

- | - |

NOTICE:

- When rotating the spiral cable sub-assembly, make sure to push on the interlock shown in the illustration to release the interlock mechanism.

- As the spiral cable sub-assembly may break, do not rotate the spiral cable sub-assembly more than the specified amount.

(1) Set the spiral cable sub-assembly to the center position.

Click here

(2) Measure the resistance between each terminal of the spiral cable sub-assembly according to the value(s) in the table below.

(3) After setting the spiral cable sub-assembly to the center position, rotate the spiral cable sub-assembly 2.5 times clockwise, and measure the resistance according to the value(s) in the table below. Then rotate the spiral cable sub-assembly 5 times counterclockwise, and measure the resistance according to the value(s) in the table below.

(4) After setting the spiral cable sub-assembly to the center position, rotate the spiral cable sub-assembly 2.5 times clockwise. Then while rotating the spiral cable sub-assembly 5 times counterclockwise, measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I82-2 (ECC) - z3-12 (ECC) |

Always | 3 Ω or less |

|

I82-4 (EAU) - z3-10 (EAU) |

Always | 3 Ω or less |

|

I82-5 (AU2) - z3-9 (AU2) |

Always | 3 Ω or less |

|

I82-6 (DIST) - z3-8 (DIST) |

Always | 3 Ω or less |

|

I82-7 (HO) - A (HO) | Always |

3 Ω or less |

|

I82-9 (IL-2) - z3-6 (IL-2) |

Always | 3 Ω or less |

|

I82-10 (+DP2) - z3-5 (+DP2) |

Always | 3 Ω or less |

|

I82-11 (+DP) - z3-4 (+DP) |

Always | 3 Ω or less |

|

I82-12 (AU1) - z3-3 (AU1) |

Always | 3 Ω or less |

|

I82-13 (CCS) - z3-2 (CCS) |

Always | 3 Ω or less |

|

I82-14 (IL+2) - z3-1 (IL+2) |

Always | 3 Ω or less |

|

I203-2 (BHT) - z35-4 (BHT) |

Always | 3 Ω or less |

|

I203-4 (EHT) - z35-1 (EHT) |

Always | 3 Ω or less |

|

I22-1 (D+) - z33-2 (D+) |

Always | Below 1 Ω |

|

I22-2 (D-) - z33-1 (D-) |

Always | Below 1 Ω |

|

I22-3 (D2-) - z34-1 (D2-) |

Always | Below 1 Ω |

|

I22-4 (D2+) - z34-2 (D2+) |

Always | Below 1 Ω |

If the result is not as specified, replace the spiral cable sub-assembly.