Toyota Corolla Cross: Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid (B279986)

DESCRIPTION

The ECM stores this DTC when a communication line between the ECM and transponder key ECU assembly is malfunctioning or the communication ID of the ECM and transponder key ECU assembly do not match.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B279986 |

Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid |

One of the following conditions is met:

|

| DTC Output Confirmation Operation:

|

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Engine cannot be started |

- |

|

DTC No. | Data List and Active Test |

|---|---|

|

B279986 | - |

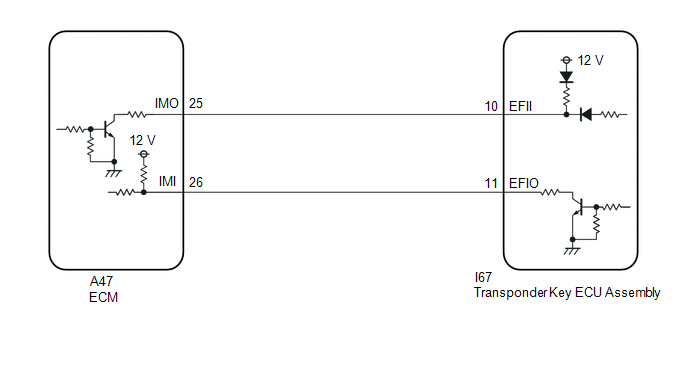

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- If the transponder key ECU assembly or ECM is replaced, refer to Registration.

Click here

.gif)

- After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

HINT:

If transponder key ECU assembly DTCs are output simultaneously, troubleshoot the transponder key ECU assembly DTCs first.

PROCEDURE

| 1. |

REGISTER ECU COMMUNICATION ID |

(a) Reregister the ECU communication ID.

|

| 2. |

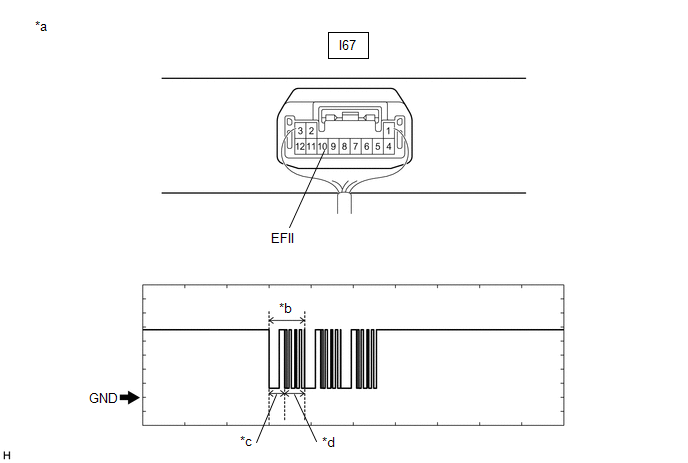

INSPECT TRANSPONDER KEY ECU ASSEMBLY (TERMINAL EFII) |

(a) Using an oscilloscope, check the waveform.

|

*a | Component with harness connected (Transponder Key ECU Assembly) |

*b | Waveform |

|

*c | Approximately 160 ms. |

*d | Approximately 270 ms. |

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

I67-10 (EFII) - Body ground |

Within 3 seconds of starter operation and initial combustion, or within 3 seconds of ignition switch first being turned to ON after cable disconnected and reconnected to negative (-) auxiliary battery terminal |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

OK:

Waveform is similar to that shown in the illustration.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (Terminal EFII stuck low (2.4 V or less)) |

B |

| NG (Terminal EFII stuck high (12 V) or abnormal waveform) |

C |

| B |

.gif) | GO TO STEP 6 |

| C |

.gif) | REPLACE ECM

|

|

| 3. |

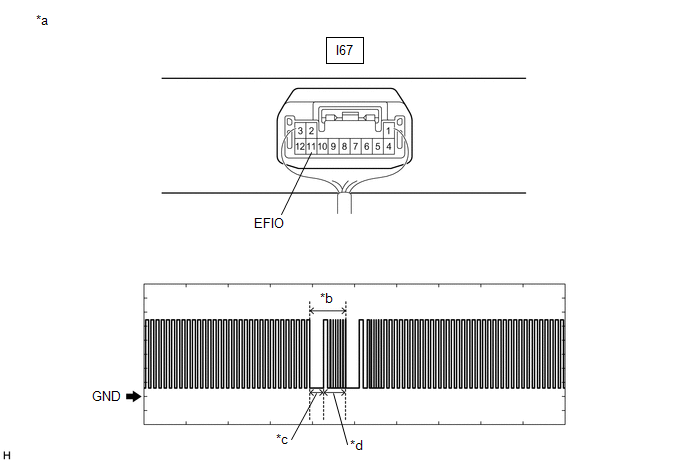

INSPECT TRANSPONDER KEY ECU ASSEMBLY (TERMINAL EFIO) |

(a) Using an oscilloscope, check the waveform.

|

*a | Component with harness connected (Transponder Key ECU Assembly) |

*b | Waveform |

|

*c | Approximately 160 ms. |

*d | Approximately 270 ms. |

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

I67-11 (EFIO) - Body ground |

Within 3 seconds of starter operation and initial combustion, or within 3 seconds of ignition switch first being turned to ON after cable disconnected and reconnected to negative (-) auxiliary battery terminal |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

OK:

Waveform is similar to that shown in the illustration.

| NG | .gif) | REPLACE TRANSPONDER KEY ECU ASSEMBLY

|

|

| 4. |

REGISTER ECU COMMUNICATION ID |

(a) Reregister the ECU communication ID.

|

| 5. |

CHECK WHETHER ENGINE STARTS |

(a) Using a registered door control transmitter assembly, turn the ignition switch to ON.

(b) Check that the engine starts 5 seconds after the ignition switch was turned to ON.

OK:

Engine starts normally.

| OK | .gif) | END (COMMUNICATION ID REGISTRATION WAS DEFECTIVE) |

| NG | .gif) | REPLACE ECM

|

| 6. |

INSPECT ECM (IMO TERMINAL VOLTAGE) |

(a) Disconnect the A47 ECM connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Result |

|---|---|---|

|

A47-25 (IMO) - Body ground |

Ignition switch turned to ON using registered door control transmitter assembly |

Terminal IMO stuck low (2.4 V or less) |

|

Terminal IMO stuck high (12 V) or abnormal waveform |

|

Result | Proceed to |

|---|---|

|

Terminal IMO stuck low (2.4 V or less) |

A |

| Terminal IMO stuck high (12 V) or abnormal waveform |

B |

| B |

.gif) | REPLACE ECM

|

|

| 7. |

CHECK HARNESS AND CONNECTOR (TRANSPONDER KEY ECU ASSEMBLY - ECM) |

(a) Disconnect the I67 transponder key ECU assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

| I67-10 (EFII) - A47-25 (IMO) |

Always | Below 1 Ω |

|

I67-10 (EFII) or A47-25 (IMO) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE TRANSPONDER KEY ECU ASSEMBLY

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)