Toyota Corolla Cross: Brake Warning Light Remains ON

DESCRIPTION

This procedure is for troubleshooting when the brake system warning light (red indicator) remains on but no DTCs are output.

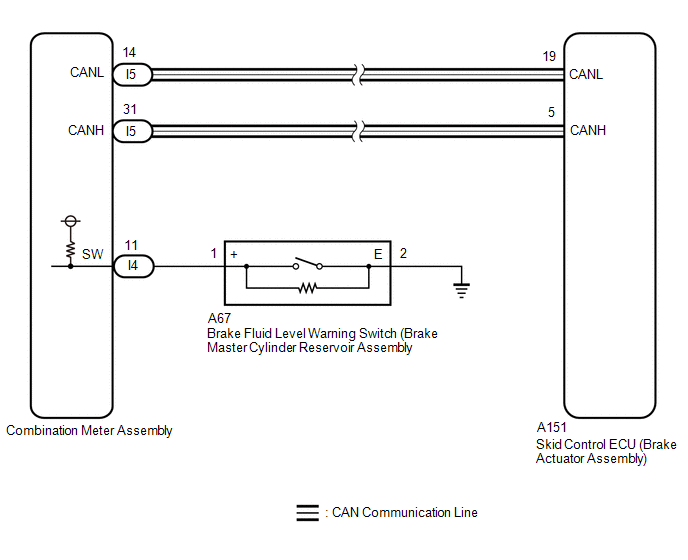

The skid control ECU (brake actuator assembly) controls the brake system warning light (red indicator) in the combination meter assembly via CAN communication.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Before performing this procedure, depress the brake pedal and confirm that the stop lights illuminate.

PROCEDURE

|

1. |

PRE-CHECK |

(a) Check that all of the following conditions required for the brake system warning light (red indicator) to turn off are met:

(1) The ABS warning light is not illuminated.

HINT:

If the ABS warning light remains illuminated, make sure that the conditions required for the ABS warning light to turn off are met.

Click here .gif)

(2) The brake fluid level in the brake master cylinder reservoir assembly is not low.

(3) Ensure that the brake booster has sufficient vacuum.

HINT:

When the vacuum inside the brake booster decreases, the brake system warning light (red indicator) comes on.

|

|

2. |

CHECK VEHICLE CONTROL HISTORY (RoB) (ELECTRONICALLY CONTROLLED BRAKE SYSTEM AND ELECTRIC PARKING BRAKE SYSTEM) |

(a) Using the GTS, check for Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

HINT:

If vehicle control history (RoB) is stored when the electronically controlled brake system and electric parking brake system are suspended, the brake system warning light (red indicator) illuminates.

|

Result |

Proceed to |

|---|---|

|

There is no vehicle control history (RoB) for when the electronically controlled brake system and electric parking brake system were suspended. |

A |

|

There is vehicle control history (RoB) for when the electronically controlled brake system and/or electric parking brake system were suspended. |

B |

| B | .gif)

|

PERFORM TROUBLESHOOTING AND REPAIR REGARDING VEHICLE CONTROL HISTORY (RoB) NOTICE: After performing troubleshooting and repair regarding vehicle control history (RoB), clear the vehicle control history (RoB). |

|

|

3. |

INSPECT BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A67 brake fluid level warning switch (brake master cylinder reservoir assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

HINT:

A float is located inside the reservoir. Its position changes according to the brake fluid level.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (+) - 2 (E) |

Switch off (float up) |

1.9 to 2.1 kΩ |

|

1 (+) - 2 (E) |

Switch on (float down) |

Below 1 Ω |

(e) If there is no problem after finishing the above check, adjust the brake fluid level to the MAX level.

| NG | .gif)

|

REPLACE BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the I4 combination meter assembly connector.

(c) Disconnect the A67 brake fluid level warning switch (brake master cylinder reservoir assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I4-11 (SW) - A67-1 (+) |

Always |

Below 1 Ω |

|

I4-11 (SW) or A67-1 (+) - Body ground |

Always |

10 kΩ or higher |

|

A67-2 (E) - Body ground |

1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal |

Below 1 Ω |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT COMBINATION METER ASSEMBLY |

(a) Perform the Active Test of the combination meter assembly using the GTS.

Click here .gif)

|

Tester Display |

|---|

|

Brake Warning |

(b) Check the combination meter assembly.

OK:

The brake system warning light (red indicator) turns on or off in accordance with GTS operation.

| OK | .gif)

|

REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif)

|

INSPECT METER / GAUGE SYSTEM |

.gif)