Toyota Corolla Cross: Brake System Control Module "A" System Voltage Line Internal Electronic Failure (C117A49,C137BA2)

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS, brake assist, regenerative braking, etc. operation.

This DTC is stored when the +BS terminal voltage meets one of the DTC detection conditions due to a malfunction in the power supply or charging circuit such as the auxiliary battery or DC/DC converter circuit, etc.

The DTC is cleared when the +BS terminal voltage returns to normal.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Note |

|---|---|---|---|---|---|---|

|

C117A49 |

Brake System Control Module "A" System Voltage Line Internal Electronic Failure |

The vehicle speed is 15 km/h (9 mph) or more and the +BS terminal voltage is 9.6 V or more, the skid control ECU (brake actuator assembly) turns on more than one valve at the same time within a short period of time and the valve relay supply voltage drop exceeds the threshold.* |

|

Comes on |

Brake/EPB |

|

|

C137BA2 |

Brake System Control Module "A" System Voltage System Voltage Low |

Any of the following is detected:

|

|

Does not come on |

Brake/EPB |

Output ECU: Skid control ECU (brake actuator assembly) |

*: The skid control ECU (brake actuator assembly) monitors the resistance of the power source line at the +BS terminal. A malfunction is detected when an abnormality occurs in the +BS terminal wire harness or its connection and the skid control ECU (brake actuator assembly) determines that the wiring resistance at the +BS terminal exceeds the standard resistance.

MONITOR DESCRIPTION

When the vehicle speed is more than a certain value, the supply voltage of the skid control ECU (brake actuator assembly) is a certain value or more, the brake pedal is not depressed, and the resistance of the solenoid supply voltage line exceeds a certain value a certain number of times, the skid control ECU (brake actuator assembly) illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

C117A: Supply voltage line test |

|

Required Sensors/Components(Main) |

Skid control ECU (brake actuator assembly) |

|

Required Sensors/Components(Related) |

Speed sensor Skid control ECU (brake actuator assembly) Stop light switch assembly |

|

Frequency of Operation |

During initial checking |

|

Duration |

- |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

TMC's intellectual property |

- |

CONFIRMATION DRIVING PATTERN

NOTICE:

When performing the normal judgment procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off.

- Turn the ignition switch to ON (READY) and turn the GTS on.

- Drive the vehicle at 15 km/h (9 mph) or more for 1 second. [*]

HINT:

[*]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Chassis / Brake/EPB* / Utility / All Readiness.

*: Electric Parking Brake System

- Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform driving pattern again.

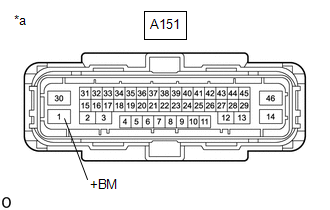

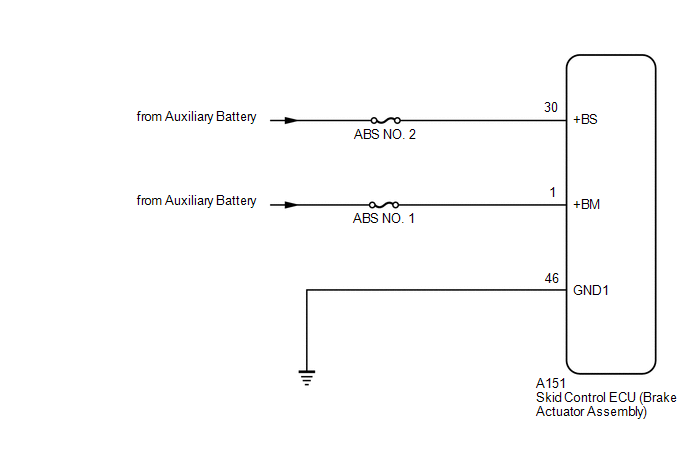

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before performing troubleshooting, make sure to confirm that the auxiliary

battery voltage is normal.

Click here

.gif)

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A151-30 (+BS) - Body ground |

Always |

11 to 14 V |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

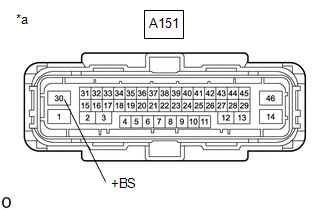

2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A151-1 (+BM) - Body ground |

Always |

11 to 14 V |

| OK | .gif)

|

REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)