Toyota Corolla Cross: Back-up Light Circuit

DESCRIPTION

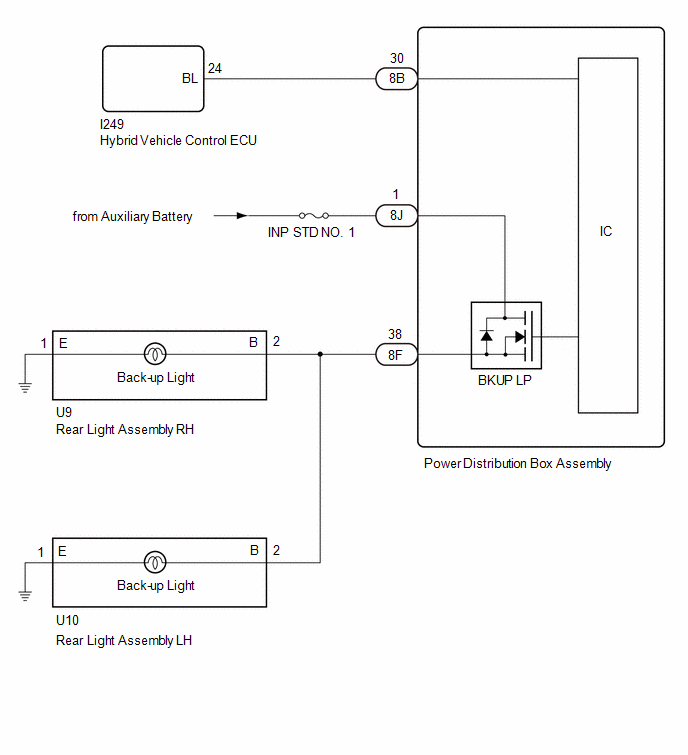

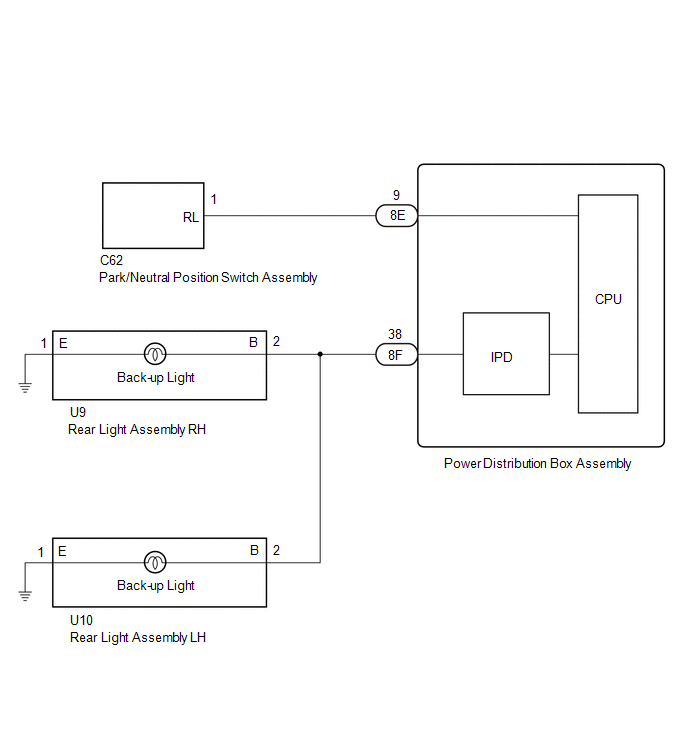

The power distribution box assembly controls the back-up lights via the BKUP LP relay.

WIRING DIAGRAM

for HEV Model

for Gasoline Model

PROCEDURE

| 1. |

CHECK VEHICLE TYPE |

(a) Check vehicle type.

|

Result | Proceed to |

|---|---|

|

for HEV Model | A |

|

for Gasoline Model | B |

| B |

.gif) | GO TO STEP 10 |

|

| 2. |

READ VALUE USING GTS |

(a) Turn the ignition switch to ON.

(b) Move the shift lever to R.

(c) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Fuse Shut Off Status |

Back-up light fuse shut off status |

OFF or ON | OFF: Fuse has no shut off history ON: Fuse has shut off history |

- |

|

Tester Display |

|---|

| Back-up Light Fuse Shut Off Status |

OK:

The Data List value displays "OFF".

| NG | .gif) | GO TO STEP 8 |

|

| 3. |

READ VALUE USING GTS |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Input Signal |

Back-up light input | OFF or ON |

OFF: Shift lever in any position other than R ON: Shift lever in R |

- |

|

Tester Display |

|---|

| Back-up Light Input Signal |

OK:

Display changes according to shift lever operation.

| NG | .gif) | GO TO STEP 6 |

|

| 4. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the 8J power distribution box assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Switch Condition |

Specified Condition |

|---|---|---|

|

8J-1 - Body ground | Ignition switch off |

11 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

CHECK HARNESS AND CONNECTOR (REAR LIGHT ASSEMBLY - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the U9 rear light assembly RH connector.

(b) Disconnect the U10 rear light assembly LH connector.

(c) Disconnect the 8F power distribution box assembly connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U9-2 (B) - 8F-38 | Always |

Below 1 Ω |

|

U10-2 (B) - 8F-38 | Always |

Below 1 Ω |

| OK | .gif) | REPLACE POWER DISTRIBUTION BOX ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 6. |

CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the I249 hybrid vehicle control ECU connector.

(b) Disconnect the 8B power distribution box assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-24 (BL) - 8B-30 |

Always | Below 1 Ω |

|

I249-24 (BL) - Body ground |

Always | 10 kΩ or higher |

|

8B-30 - Body ground | Always |

10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 7. |

CHECK HYBRID VEHICLE CONTROL ECU (OUTPUT VOLTAGE) |

| (a) Connect the I249 hybrid vehicle control ECU connector. |

|

(b) Connect the 8B power distribution box assembly connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

8B-30 - Body ground | Ignition switch ON, reverse (R) not selected |

Below 1 V |

|

8B-30 - Body ground | Ignition switch ON, reverse (R) selected |

11 to 14 V |

| OK | .gif) | REPLACE POWER DISTRIBUTION BOX ASSEMBLY |

| NG | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

| 8. |

CHECK REAR LIGHT ASSEMBLY LH |

(a) Disconnect the U1 rear light assembly LH connector.

(b) Turn the ignition switch to ON.

(c) Move the shift lever to R.

(d) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Fuse Shut Off Status |

Back-up light fuse shut off status |

OFF or ON | OFF: Fuse has no shut off history ON: Fuse has shut off history |

- |

|

Tester Display |

|---|

| Back-up Light Fuse Shut Off Status |

OK:

The Data List value displays "OFF".

| OK | .gif) | REPLACE REAR LIGHT ASSEMBLY LH |

|

| 9. |

CHECK REAR LIGHT ASSEMBLY RH |

(a) Disconnect the U9 rear light assembly RH connector.

(b) Turn the ignition switch to ON.

(c) Move the shift lever to R.

(d) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Fuse Shut Off Status |

Back-up light fuse shut off status |

OFF or ON | OFF: Fuse has no shut off history ON: Fuse has shut off history |

- |

|

Tester Display |

|---|

| Back-up Light Fuse Shut Off Status |

OK:

The Data List value displays "OFF".

| OK | .gif) | REPLACE REAR LIGHT ASSEMBLY RH |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 10. |

READ VALUE USING GTS |

(a) Turn the ignition switch to ON.

(b) Move the shift lever to R.

(c) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Fuse Shut Off Status |

Back-up light fuse shut off status |

OFF or ON | OFF: Fuse has no shut off history ON: Fuse has shut off history |

- |

|

Tester Display |

|---|

| Back-up Light Fuse Shut Off Status |

OK:

The Data List value displays "OFF".

| NG | .gif) | GO TO STEP 15 |

|

| 11. |

READ VALUE USING GTS |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Input Signal |

Back-up light input | OFF or ON |

OFF: Shift lever in any position other than R ON: Shift lever in R |

- |

|

Tester Display |

|---|

| Back-up Light Input Signal |

OK:

Display changes according to shift lever operation.

| NG | .gif) | GO TO STEP 14 |

|

| 12. |

CHECK HARNESS AND CONNECTOR (REAR LIGHT ASSEMBLY RH - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the U9 rear light assembly RH connector.

(b) Disconnect the 8F power distribution box assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U9-2 (B) - 8F-38 | Always |

Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 13. |

CHECK PARK/NEUTRAL POSITION SWITCH ASSEMBLY (OUTPUT VOLTAGE) |

(a) Disconnect the 8E power distribution box assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

8E-9 - Body ground | Ignition switch ON, shift lever not in R |

Below 1 V |

|

8E-9 - Body ground | Ignition switch ON, shift lever in R |

11 to 14 V |

| OK | .gif) | REPLACE POWER DISTRIBUTION BOX ASSEMBLY |

| NG | .gif) | CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY) |

| 14. |

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY) |

(a) Disconnect the C62 park/neutral position switch assembly connector.

(b) Disconnect the 8E power distribution box assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

C62-1 (RL) - 8E-9 | Always |

Below 1 Ω |

|

C62-1 (RL) - Body ground |

Always | 10 kΩ or higher |

|

8E-9 - Body ground | Always |

10 kΩ or higher |

| OK | .gif) | REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY for 2WD: Click here for AWD: Click here

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 15. |

CHECK REAR LIGHT ASSEMBLY RH |

(a) Disconnect the U9 rear light assembly RH connector.

(b) Turn the ignition switch to ON.

(c) Move the shift lever to R.

(d) Read the Data List according to the display on the GTS.

Body Electrical > Power Distribution Box > Data List|

Tester Display | Measurement Item |

Normal Condition | Reference Value |

Diagnostic Note |

|---|---|---|---|---|

|

Back-up Light Fuse Shut Off Status |

Back-up light fuse shut off status |

OFF or ON | OFF: Fuse has no shut off history ON: Fuse has shut off history |

- |

|

Tester Display |

|---|

| Back-up Light Fuse Shut Off Status |

OK:

The Data List value displays "OFF".

| OK | .gif) | REPLACE BACK-UP LIGHT RH |

|

| 16. |

CHECK HARNESS AND CONNECTOR (REAR LIGHT ASSEMBLY - POWER DISTRIBUTION BOX ASSEMBLY) |

(a) Disconnect the 8F power distribution box assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U10-2 (B) - Body ground |

Always | 10 kΩ or higher |

|

8F-38 - Body ground | Always |

10 kΩ or higher |

| OK | .gif) | REPLACE POWER DISTRIBUTION BOX ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)

.png)

.gif)