Toyota Corolla Cross: Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the CVT fluid replacement are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effect/Inoperative Function When Necessary Procedures are not Performed |

Link |

|---|---|---|---|

|

CVT fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

|

Bleed air from oil pump (continuously variable transaxle assembly) |

Stop and Start System |

|

PROCEDURE

1. PRECAUTIONS AND WORK DESCRIPTION

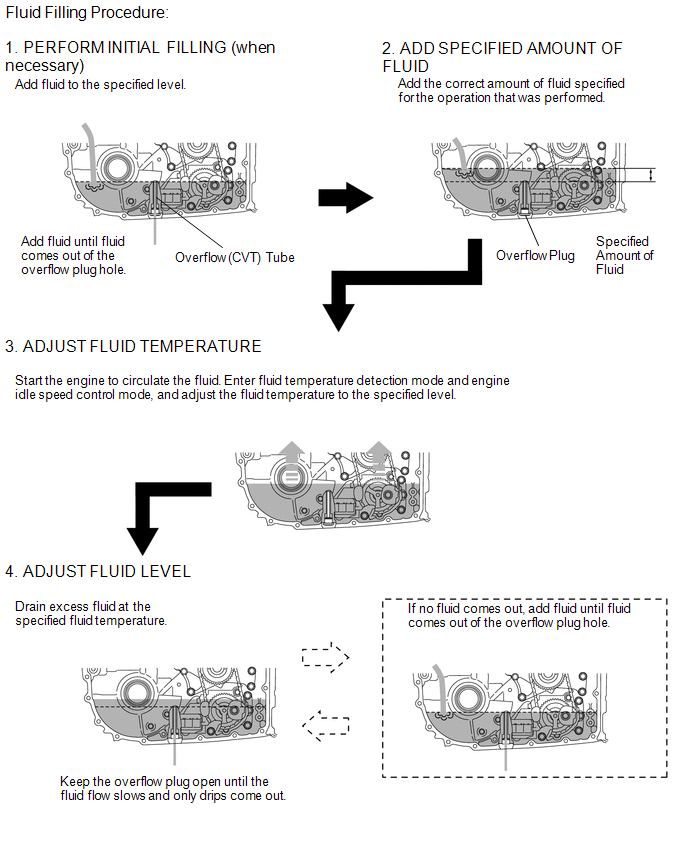

(a) The K120F continuously variable transaxle assembly does not have an oil filler tube or oil level gauge. When adding fluid, add fluid through the refill hole in the continuously variable transaxle assembly. The fluid level can be adjusted by draining excess fluid (allowing excess fluid to overflow) through the overflow (CVT) tube of the transaxle case sub-assembly.

HINT:

"Overflow" indicates the condition under which fluid comes out of the overflow plug hole.

(b) When adding fluid, add the specified amount of fluid while the engine assembly is cold. Then, warm up the engine assembly to circulate the fluid in the continuously variable transaxle assembly and adjust the fluid level with the engine idling at the specified fluid temperature.

(c) The K120 continuously variable transaxle assembly requires Toyota Genuine CVT fluid FE.

(d) When adjusting the fluid level, park the vehicle on level ground (make sure that the tilt angle from the front to rear and side to side of the vehicle is within +/-1°).

(e) When adjusting the fluid level, turn off all electrical systems, such as the air conditioning, lighting system, electric fan and audio system, to reduce load.

(f) The fluid temperature shown in the text is "A/T Oil Temperature No. 1" displayed on the GTS.

(g) Fluid level adjustment should be performed according to the following procedure and notes.

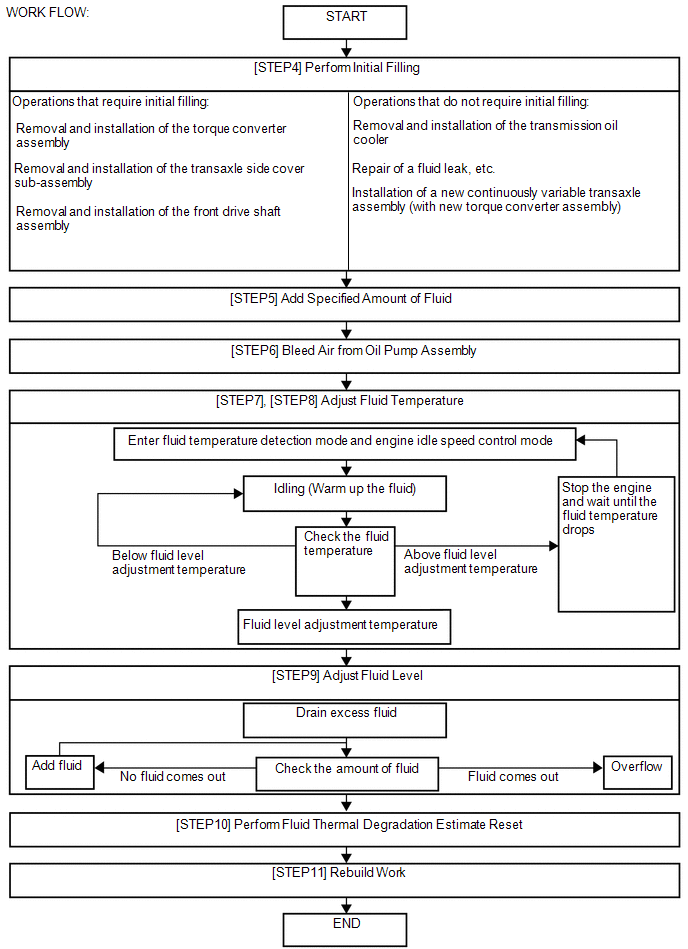

2. WORK FLOW

(a) The adjustment should be performed according to the procedures referenced in the work flow below.

3. PREPARATION WORK

NOTICE:

If the continuously variable transaxle assembly is hot (fluid temperature is high), wait until the fluid temperature becomes the same as the ambient temperature before starting the following procedure (recommended fluid temperature: approximately 20°C (68°F)).

(a) Lift the vehicle.

NOTICE:

Set the vehicle on a lift so that the vehicle is kept level when it is lifted up (make sure that the tilt angle from the front to rear and side to side of the vehicle is within +/-1°).

(b) Remove the No. 1 engine under cover assembly.

Click here .gif)

.gif)

(c) Remove the rear engine under cover LH.

Click here .gif)

.gif)

4. PERFORM INITIAL FILLING

NOTICE:

After performing either of the following operations, it is not necessary to perform the initial filling procedure. Proceed to the Add Specified Amount of Fluid procedure (Step 5).

|

Operations that do not Require Initial Filling |

|---|

|

|

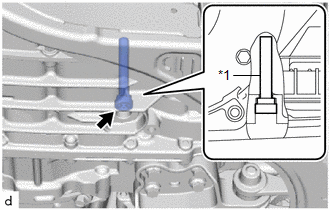

(a) Remove the refill plug and gasket from the rear transaxle case sub-assembly. |

|

|

(b) Using a 10 mm hexagon socket wrench, remove the overflow plug and gasket from the transaxle case sub-assembly. NOTICE:

|

|

|

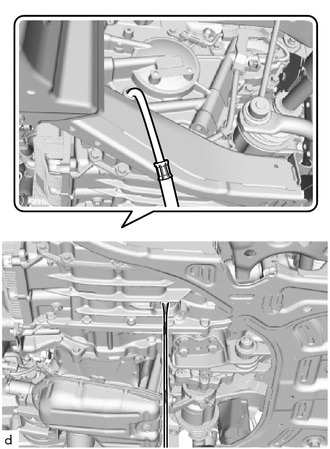

(c) Using a 6 mm hexagon socket wrench, check that the overflow (CVT) tube is tightened to the specified torque. Torque: 0.8 N·m {8 kgf·cm, 7 in·lbf} NOTICE: If the overflow (CVT) tube is not tightened to the specified torque, the amount of fluid cannot be precisely adjusted. HINT: To check the torque of the overflow (CVT) tube, insert a 6 mm hexagon socket wrench into the overflow plug hole. |

|

(d) Perform initial filling.

|

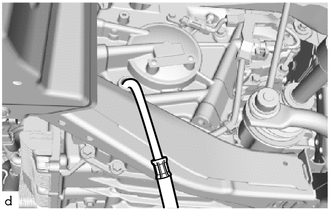

(1) Add fluid to the refill hole until it flows out of the overflow plug hole. NOTICE: Use Toyota Genuine CVT fluid FE. Using CVT (Continuously Variable Transaxle) fluid other than the above type may cause abnormal noise or vibration, or damage the CVT (Continuously Variable Transaxle) of your vehicle. |

|

|

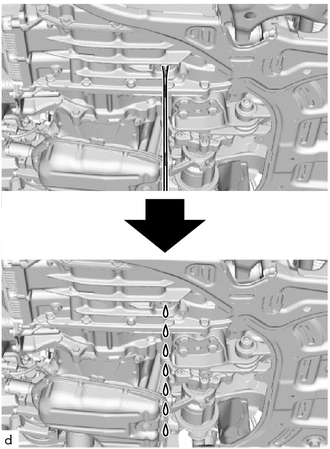

(e) Wait until the fluid flow slows and only drips come out. |

|

|

(f) Using a 10 mm hexagon socket wrench, temporarily install the overflow plug and gasket to the transaxle case sub-assembly. HINT: Reuse the old gasket as the overflow plug will be removed again to adjust the fluid level. |

|

|

(g) Temporarily install the refill plug and gasket to the rear transaxle case sub-assembly. HINT: Reuse the old gasket as the refill plug will be removed again to adjust the fluid level. |

|

5. ADD SPECIFIED AMOUNT OF FLUID

|

(a) Remove the refill plug and gasket from the rear transaxle case sub-assembly (when initial filling was not performed). |

|

|

(b) Add fluid to the refill hole using the correct amount of fluid as listed in the table below. NOTICE: Use Toyota Genuine CVT fluid FE. Using CVT (Continuously Variable Transaxle) fluid other than the above type may cause abnormal noise or vibration, or damage the CVT (Continuously Variable Transaxle) of your vehicle. HINT: The refill amount differs depending on the operation that was performed. Standard Capacity

|

|

||||||||||||||||||||||||

|

(c) Temporarily install the refill plug and gasket to the rear transaxle case sub-assembly to avoid fluid spillage. HINT: Reuse the old gasket as the refill plug will be removed again to adjust the fluid level. |

|

(d) Lower the vehicle.

6. BLEED AIR FROM OIL PUMP ASSEMBLY

Click here .gif)

7. ADJUST FLUID TEMPERATURE (when Using the GTS)

(a) Connect the GTS to the DLC3 with the ignition switch off.

(b) Turn the ignition switch to ON and turn the GTS on.

NOTICE:

To reduce load, make sure that all electrical systems, such as the air conditioning, lighting system, electric fans and audio system, are off.

(c) Enter the following menus: Powertrain / Transmission / Active Test / Activate the TC Terminal.

Powertrain > Transmission > Active Test|

Active Test Display |

|---|

|

Activate the TC Terminal |

|

Data List Display |

|---|

|

A/T Oil Temperature No.1 |

(d) According to the display on the GTS, perform the Active Test "Activate the TC Terminal".

HINT:

The indicator lights on the combination meter blink to indicate that a DTC has been stored when the Active Test "Activate the TC Terminal" is performed.

(e) Select the Data List item: A/T Oil Temperature No. 1.

(f) Depress and hold the brake pedal.

(g) Start the engine.

NOTICE:

To reduce load, make sure that all electrical systems, such as the air conditioning, lighting system, electric fan and audio system, are off.

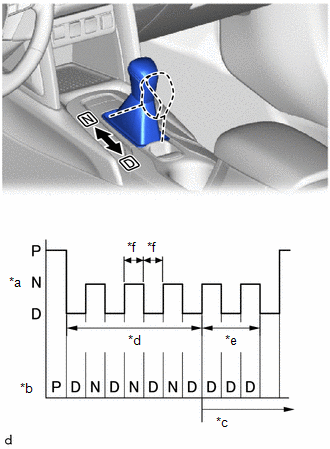

(h) Slowly move the shift lever from P to D, and then back to P (keep the shift lever in each position for approximately 3 seconds).

HINT:

Slowly move the shift lever to circulate the fluid through each part of the continuously variable transaxle assembly.

|

(i) While observing the D shift indicator on the combination meter, move the shift lever back and forth between N and D at an interval of less than 1.5 seconds for 6 seconds or more. NOTICE: Do not pause for 1.5 seconds or more. HINT: Performing this operation will cause the vehicle to enter fluid temperature detection mode. |

|

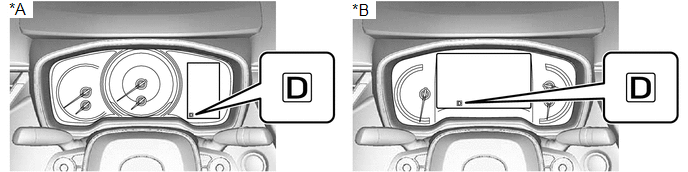

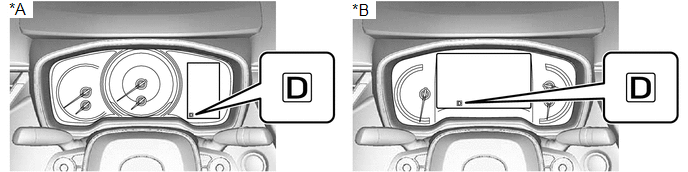

(j) Check that the D shift indicator comes on for 2 seconds.

|

*A |

for Type A |

*B |

for Type B |

HINT:

- When fluid temperature detection mode is activated, the D shift indicator on the combination meter comes on for 2 seconds.

- If the D shift indicator does not come on for 2 seconds, return to the first step (perform the Active Test "Connect the TC and TE1 / ON") and perform the procedure again.

(k) Move the shift lever to P.

(l) Release the brake pedal.

(m) According to the display on the GTS, perform the Active Test "Connect the TC and TE1 / OFF".

NOTICE:

Make sure that terminals are not connected. If the terminals are connected, the fluid level cannot be precisely adjusted due to fluctuations in engine speed.

HINT:

- Disconnecting the terminals activates engine idle speed control mode.

- In engine idle speed control mode, engine idle speed control starts when the fluid temperature reaches the specified temperature and the engine speed is maintained.

- Even after the terminals are disconnected, fluid temperature detection mode remains active until the ignition switch is turned off.

(n) Adjust the fluid temperature to the fluid level adjustment temperature.

(1) Check the fluid temperature by monitoring the D shift indicator.

Relationship between Fluid Level Adjustment Temperature and the D Shift Indicator:

|

Below Fluid Level Adjustment Temperature |

Fluid Level Adjustment Temperature |

Above Fluid Level Adjustment Temperature |

|

|---|---|---|---|

|

Fluid Temperature ("A/T Oil Temperature No. 1" displayed on the GTS) |

35°C (95°F) or less |

35 to 45°C (95 to 113°F) |

45°C (113°F) or more |

|

D Shift Indicator |

Off |

On |

Blinks |

HINT:

- In fluid temperature detection mode, the D shift indicator comes on, goes off, or blinks depending on the fluid temperature.

- The fluid filling procedure should be performed when the D shift indicator is on (the fluid temperature is within the fluid level adjustment temperature range).

(2) If the D shift indicator is on [Fluid Level Adjustment Temperature: 35 to 45°C (95 to 113°F)]: Immediately proceed to the Adjust Fluid Level (Step 8).

(3) Adjust the fluid temperature.

- If the D shift indicator is off [Below Fluid Level Adjustment Temperature: 35°C (95°F) or less]: Warm up the engine with the engine idling in engine idle speed control mode until the D shift indicator turns on.

- If the D shift indicator is on [Fluid Level Adjustment Temperature: 35 to 45°C (95 to 113°F)]: Immediately proceed to Adjust Fluid Level (Step 8).

- If the D shift indicator is blinking [Above Fluid Level Adjustment Temperature: 45°C (113°F) or more]: Stop the engine and wait until the fluid temperature drops to 35°C (95°F) or less (the D shift indicator goes off). Then perform the adjust fluid temperature procedure again from the beginning.

8. ADJUST FLUID TEMPERATURE (when Not Using the GTS)

(a) Turn the ignition switch off.

(b) Depress and hold the brake pedal.

(c) Start the engine. [#1]

NOTICE:

To reduce load, make sure that all electrical systems, such as the air conditioning, lighting system, electric fan and audio system, are off.

(d) Slowly move the shift lever from P to D, and then back to P (keep the shift lever in each position for approximately 3 seconds). [#2]

HINT:

Slowly move the shift lever to circulate the fluid through each part of the continuously variable transaxle assembly.

|

(e) While observing the D shift indicator on the combination meter, move the shift lever back and forth between N and D at an interval of less than 1.5 seconds for 12 seconds or more. [#3] NOTICE: Do not pause for 1.5 seconds or more. HINT:

|

|

(f) Check that the D shift indicator comes on for 2 seconds.

|

*A |

for Type A |

*B |

for Type B |

HINT:

- When fluid temperature detection mode is activated, the D shift indicator on the combination meter comes on for 2 seconds.

- If the D shift indicator does not come on for 2 seconds, return to the first step (Start the engine. [#1]) and perform the procedure again.

- Fluid temperature detection mode is active until the ignition switch is turned off.

(g) Move the shift lever to P.

(h) Release the brake pedal.

(i) Adjust the fluid temperature to the fluid level adjustment temperature.

(1) Check the fluid temperature by monitoring the D shift indicator.

Relationship between Fluid Level Adjustment Temperature and the D Shift Indicator:

|

Below Fluid Level Adjustment Temperature |

Fluid Level Adjustment Temperature |

Above Fluid Level Adjustment Temperature |

|

|---|---|---|---|

|

Fluid Temperature |

35°C (95°F) or less |

35 to 45°C (95 to 113°F) |

45°C (113°F) or more |

|

D Shift Indicator |

Off |

On |

Blinks |

HINT:

- In fluid temperature detection mode, the D shift indicator comes on, goes off, or blinks depending on the fluid temperature.

- The fluid filling procedure should be performed when the D shift indicator is on (the fluid temperature is within the fluid level adjustment temperature range).

(2) If the D shift indicator is on [Fluid Level Adjustment Temperature: 35 to 45°C (95 to 113°F)]: Immediately proceed to the Adjust Fluid Level (Step 8).

(3) Adjust the fluid temperature.

- If the D shift indicator is off [Below Fluid Level Adjustment Temperature: 35°C (95°F) or less]: Warm up the engine with the engine idling in engine idle speed control mode until the D shift indicator turns on.

- If the D shift indicator is on [Fluid Level Adjustment Temperature: 35 to 45°C (95 to 113°F)]: Immediately proceed to Adjust Fluid Level (Step 8).

- If the D shift indicator is blinking [Above Fluid Level Adjustment Temperature: 45°C (113°F) or more]: Stop the engine and wait until the fluid temperature drops to 35°C (95°F) or less (the D shift indicator goes off). Then perform the adjust fluid temperature procedure again from the beginning.

9. ADJUST FLUID LEVEL

CAUTION:

.png) Make sure not to get any of

the drained fluid on your hands, etc.

Make sure not to get any of

the drained fluid on your hands, etc. - The high temperature of the drained fluid could cause burns.

- When working near the engine room while the engine has started or the ignition

switch is ON, do not touch the rotating components such as the V-ribbed belt

or cooling fan.

.png)

- Touching the rotating components such as the V-ribbed belt or cooling fan could result in your hand or clothing getting caught and pulled in.

(a) Lift the vehicle.

NOTICE:

Set the vehicle on a lift so that the vehicle is kept level when it is lifted up (make sure that the tilt angle from the front to rear and side to side of the vehicle is within +/-1°).

|

(b) Using a 10 mm hexagon socket wrench, remove the overflow plug and gasket from the transaxle case sub-assembly. CAUTION: Be careful as the fluid coming out of the overflow plug hole is hot. |

|

(c) Check the amount of fluid that comes out of the overflow plug hole.

- If the amount of fluid that comes out of the overflow plug hole is large, proceed to step [#1].

- If no fluid comes out of the overflow plug hole, proceed to step [#2].

NOTICE:

If only a small amount of fluid (approximately 5 cc) comes out of the overflow plug hole, then only fluid remaining in the overflow (CVT) tube has come out. This condition is not considered as overflow, so it is necessary to add fluid.

(d) If the amount of fluid that comes out of the overflow plug hole is large. [#1]

|

(1) Wait until the fluid flow slows and only drips come out. HINT: The fluid flow will not stop completely because the fluid continues to expand as its temperature increases. |

|

(e) If no fluid comes out of the overflow plug hole. [#2]

|

(1) Remove the refill plug and gasket from the rear transaxle case sub-assembly. |

|

|

(2) Then add fluid through the refill hole until fluid comes out of the overflow plug hole. NOTICE: Use Toyota Genuine CVT fluid FE. Using CVT (Continuously Variable Transaxle) fluid other than the above type may cause abnormal noise or vibration, or damage the CVT (Continuously Variable Transaxle) of your vehicle. |

|

|

(3) Wait until the fluid flow slows and only drips come out. HINT: The fluid flow will not stop completely because the fluid continues to expand as its temperature increases. |

|

(f) Coat a new gasket with Toyota Genuine CVT fluid FE and install it to the overflow plug.

|

(g) Using a 10 mm hexagon socket wrench, install the overflow plug to the transaxle case sub-assembly. Torque: 49 N·m {500 kgf·cm, 36 ft·lbf} |

|

(h) Coat a new gasket with Toyota Genuine CVT fluid FE and install it to the refill plug.

|

(i) Install the refill plug to the rear transaxle case sub-assembly. Torque: 49 N·m {500 kgf·cm, 36 ft·lbf} |

|

(j) Lower the vehicle.

(k) Turn the ignition switch off.

HINT:

Turning the ignition switch off ends fluid temperature detection mode.

(l) Remove the GTS from the DLC3 (when using the GTS).

10. PERFORM FLUID THERMAL DEGRADATION ESTIMATE RESET

NOTICE:

If approximately 50% or more of the CVT fluid has been replaced during a repair of the transaxle or a similar operation, perform ATF Thermal Degradation Estimate Reset.

Click here .gif)

.gif)

11. REBUILD WORK

(a) Lift the vehicle.

(b) Clean each part.

(c) Check for fluid leaks.

(d) Install the rear engine under cover LH.

(e) Install the No. 1 engine under cover assembly.

Click here .gif)

(f) Lower the vehicle.

.png)

.png)