Toyota Corolla Cross: Terminals Of Ecu

TERMINALS OF ECU

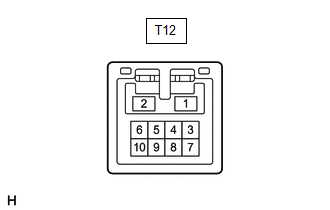

CHECK SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY)

(a) Disconnect the T12 sliding roof ECU (sliding roof drive gear sub-assembly) connector.

(b) Measure the resistance and voltage according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

T12-1 (B) - T12-2 (E) |

Auxiliary battery power supply |

Ignition switch off | 11 to 14 V |

|

T12-2 (E) - Body ground |

Ground | Always |

Below 1 Ω |

(c) Reconnect the M3 sliding roof ECU (sliding roof drive gear sub-assembly) connector.

(d) Measure the voltage according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

T12-10 (OPN) - T12-2 (E) |

Sliding roof motor open |

Ignition switch ON, OPEN switch on |

Below 1 V |

|

Ignition switch ON, OPEN switch off |

11 to 14 V | ||

|

T12-8 (CLS) - T12-2 (E) |

Sliding roof motor close |

Ignition switch ON, CLOSE switch on |

Below 1 V |

|

Ignition switch ON, CLOSE switch off |

11 to 14 V | ||

|

T12-5 (UP) - T12-2 (E) |

Sliding roof motor up |

Ignition switch ON, UP switch on |

Below 1 V |

|

Ignition switch ON, UP switch off |

11 to 14 V | ||

|

T12-9 (DWN) - T12-2 (E) |

Sliding roof motor down |

Ignition switch ON, DOWN switch on |

Below 1 V |

|

Ignition switch ON, DOWN switch off |

11 to 14 V |

(e) Measure the pulse according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

T12-7 (MPX1) - Body ground |

LIN communication line |

Ignition switch ON | Pulse generation |

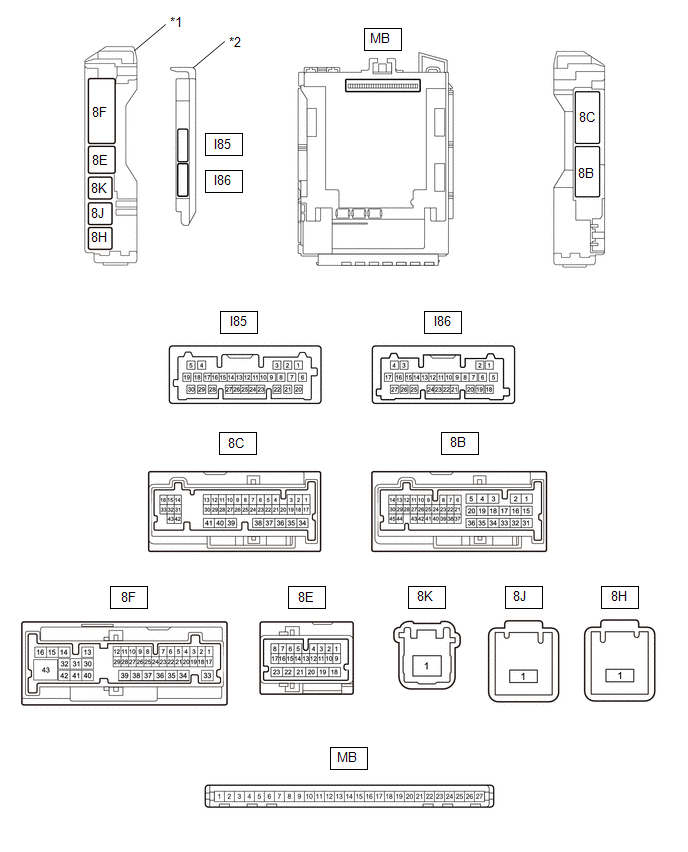

CHECK POWER DISTRIBUTION BOX ASSEMBLY AND MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

|

*1 | Power Distribution Box Assembly |

*2 | Main Body ECU (Multiplex Network Body ECU) |

(a) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

(b) Reconnect the power distribution box assembly connectors.

(c) Measure the voltage and resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connectors connected.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

MB-13 (GND1) - Body ground |

Ground | Always |

Below 1 Ω |

|

MB-14 (GND2) - Body ground |

Ground | Always |

Below 1 Ω |

|

MB-26 (BECU) - Body ground |

Auxiliary battery power supply |

Ignition switch off | 11 to 14 V |

|

MB-27 (IGR) - Body ground |

IG power supply | Ignition switch ON |

11 to 14 V |

|

Ignition switch off | Below 1 V |

(d) Reconnect the MB main body ECU (multiplex network body ECU) connector.

(e) Check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

8F-3 (FLCY) - Body ground |

Front door courtesy light switch (for LH) input |

Front door LH open → closed |

Below 1 V → 11 to 14 V or pulse output (maximum 14 V)* |

|

8F-5 (FRCY) - Body ground |

Front door courtesy light switch (for RH) input |

Front door RH open → closed |

Below 1 V → 11 to 14 V or pulse output (maximum 14 V)* |

|

8B-37 (LIN2) - Body ground |

LIN communication line |

Ignition switch ON | Pulse generation |

- *: Differs depending on the vehicle model