Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

TRANSAXLE SIDE COVER SUB-ASSEMBLY |

35015Y |

|

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

.png) |

Toyota Genuine CVT Fluid FE |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

2 |

ENGINE WIRE |

82121 |

- |

- |

- |

|

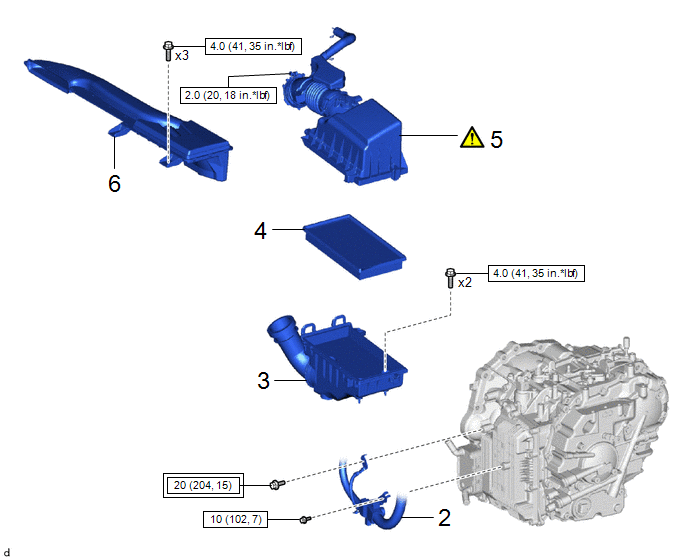

3 |

AIR CLEANER CASE SUB-ASSEMBLY |

17701 |

- |

- |

- |

|

4 |

AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

17801 |

- |

- |

- |

|

5 |

AIR CLEANER CAP WITH AIR CLEANER HOSE |

- |

|

- |

- |

|

6 |

INLET NO. 1 AIR CLEANER |

17751 |

- |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

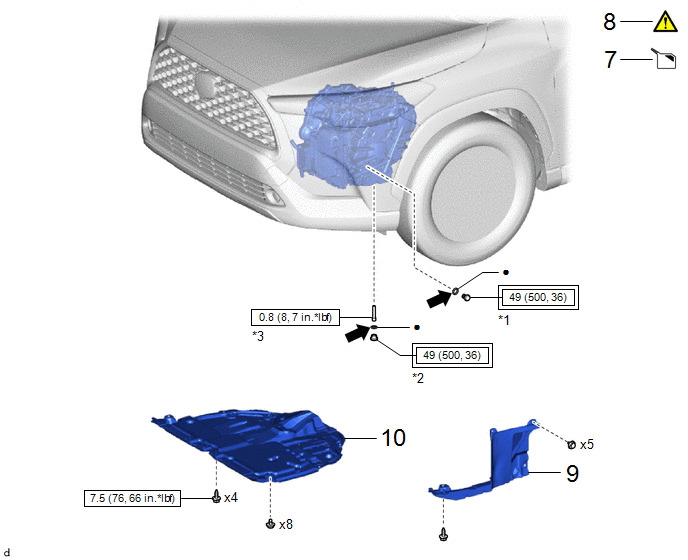

7 |

ADJUST CONTINUOUSLY VARIABLE TRANSAXLE FLUID |

- |

- |

|

- |

|

8 |

INSPECT FOR CONTINUOUSLY VARIABLE TRANSAXLE FLUID LEAK |

- |

|

- |

- |

|

9 |

INSTALL REAR ENGINE UNDER COVER LH |

51444A |

- |

- |

- |

|

10 |

INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 |

- |

- |

- |

|

*1 |

REFILL PLUG |

*2 |

OVERFLOW PLUG |

|

*3 |

OVERFLOW (CVT) TUBE |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● |

Non-reusable part |

.png) |

Toyota Genuine CVT Fluid FE |

PROCEDURE

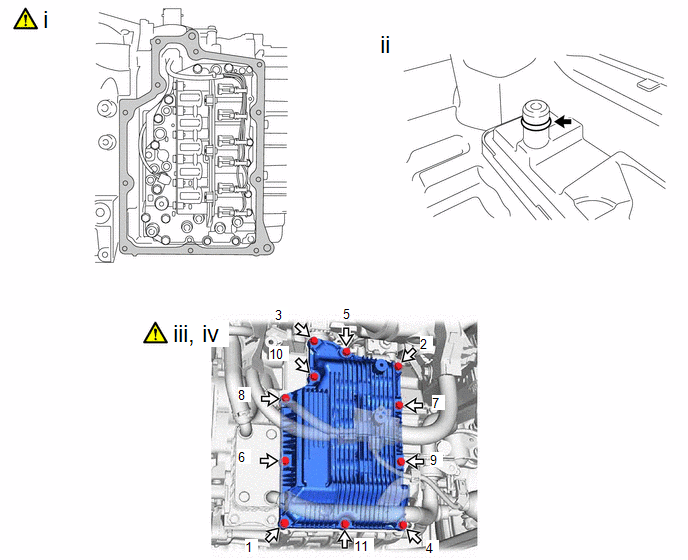

1. INSTALL TRANSAXLE SIDE COVER SUB-ASSEMBLY

.png) |

Toyota Genuine CVT Fluid FE |

.png) |

Area to be Cleaned |

(1) Clean the transaxle side cover sub-assembly installation surface of the transaxle case sub-assembly.

NOTICE:

Completely remove any oil or grease from the contact surfaces of the transaxle case sub-assembly.

(2) Coat a new O-ring with Toyota Genuine CVT fluid FE and install it to a new transaxle side cover sub-assembly.

(3) Temporarily install the transaxle side cover subassembly to the transaxle case sub-assembly with the 11 bolts.

(4) Fully tighten the 11 bolts in the order shown in the illustration.

Torque:

7.4 N·m {75 kgf·cm, 65 in·lbf}

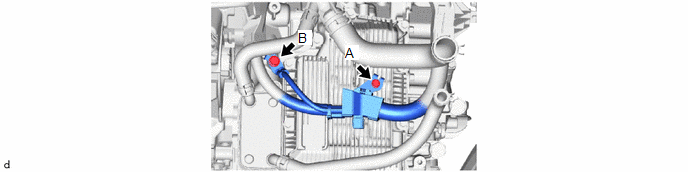

2. CONNECT ENGINE WIRE

Torque:

for Bolt A :

10 N·m {102 kgf·cm, 7 ft·lbf}

for Bolt B :

20 N·m {204 kgf·cm, 15 ft·lbf}

3. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

Click here .gif)

.gif)

4. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

5. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

.png) |

Click here |

6. INSTALL INLET NO. 1 AIR CLEANER

Click here .gif)

7. ADJUST CONTINUOUSLY VARIABLE TRANSAXLE FLUID

Click here .gif)

8. INSPECT FOR CONTINUOUSLY VARIABLE TRANSAXLE FLUID LEAK

Click here .gif)

9. INSTALL REAR ENGINE UNDER COVER LH

10. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)