Toyota Corolla Cross: All Door Entry Lock/Unlock Functions and Wireless Functions do not Operate

DESCRIPTION

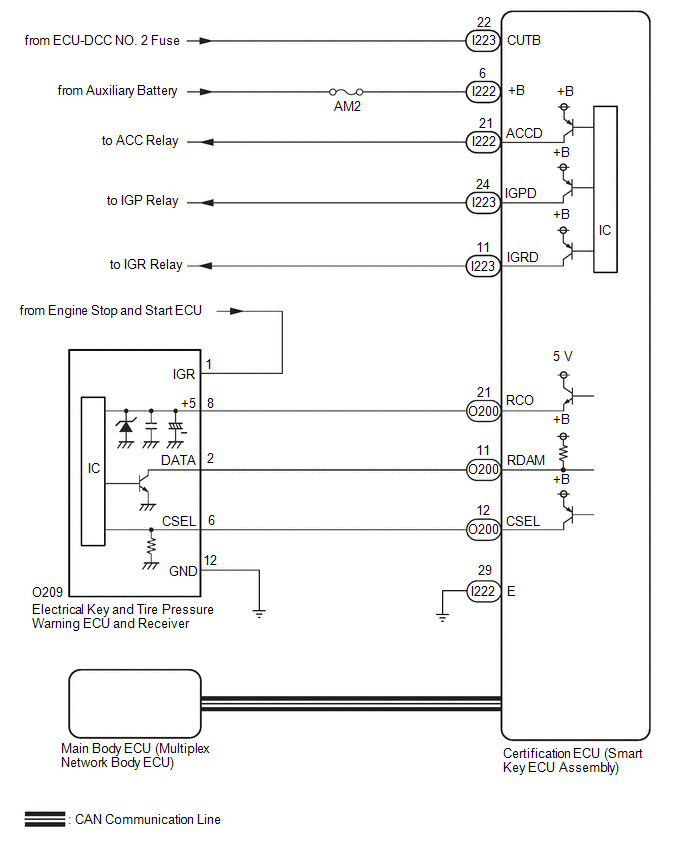

If the entry lock and wireless door lock operations cannot be performed, the electrical key and tire pressure warning ECU and receiver may be malfunctioning, or there may be wave interference or problems in the communication which is used for the entry and wireless function between the electrical key and tire pressure warning ECU and receiver and certification ECU (smart key ECU assembly).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When using the GTS with the ignition switch off, connect the GTS to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the GTS and the vehicle begins. Then select the vehicle type under manual mode and enter the following menus: Body Electrical / Smart Key. While using the GTS, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the GTS and the vehicle.

- The smart key system (for Entry Function) uses the CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the smart key system (for Entry Function) after confirming that the communication systems are functioning properly.

Click here

.gif)

- Before replacing the certification ECU (smart key ECU assembly) or main body ECU (multiplex network body ECU), refer to Precaution.

Click here

.gif)

- Check that there are no electrical key transmitter sub-assemblies in the vehicle.

- Before performing the inspection, check that DTC B124296 (wireless door lock control) is not output.

- After repair, confirm that no DTCs are output.

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. | INSPECT AUXILIARY BATTERY VOLTAGE |

(a) Measure the auxiliary battery voltage with the ignition switch off.

Standard Voltage:

11 to 14 V

HINT:

It may be possible to tell whether the auxiliary battery is discharged by operating the horn.

If the voltage is below 11 V, recharge or replace the auxiliary battery before proceeding to the next step.

|

| 2. |

CHECK ENTRY OPERATION AND WIRELESS OPERATION |

(a) Check the operation of the entry lock and unlock functions, and wireless door lock function.

| (1) Check the entry unlock function.

HINT:

|

|

| (2) Check the entry lock function.

|

|

| (3) Check the entry back door open function.

|

|

| (4) Check the entry back door lock function.

|

|

(5) Check the wireless door lock function.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

All door entry lock/unlock functions and wireless functions do not operate |

A |

| All door entry lock/unlock functions do not operate, but wireless functions operate |

B |

| Entry lock/unlock functions do not operate for one or more doors, but wireless functions operate | |

|

Entry lock function does not operate for one or more doors, but entry unlock and wireless functions operate | |

|

Entry unlock function does not operate for one or more doors, but entry lock and wireless functions operate | |

|

All entry and wireless functions operate |

C |

| B |

.gif) | GO TO PROBLEM SYMPTOMS TABLE |

| C |

.gif) | GO TO CHECK FOR INTERMITTENT PROBLEMS (VEHICLE CONTROL HISTORY (ROB)) |

|

| 3. |

CHECK DOOR AJAR WARNING |

(a) When the doors are locked by operating the entry lock function with all doors closed, check that the door ajar warning operates.

HINT:

Be sure to check the following before performing the procedure.

- Ignition switch is off.

- All the doors is close.

- The lock sensor is on or lock switch is pressed on the electrical key transmitter sub-assembly.

- Electrical key transmitter sub-assembly is in the vehicle exterior detection area.

- The customize setting Open Door Warning is Enable.

- The customize setting Wireless Lock Function with Doors Open is Disable.

|

Result | Proceed to |

|---|---|

|

The wireless buzzer does not sound |

A |

| The wireless buzzer sounds |

B |

| B |

.gif) | GO TO LIGHTING SYSTEM (Proceed to Door Courtesy Switch Circuit) |

|

| 4. |

CHECK POWER DOOR LOCK CONTROL SYSTEM |

(a) When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Power door lock function operates normally |

A |

| Power door lock function does not operate normally |

B |

| B |

.gif) | GO TO POWER DOOR LOCK CONTROL SYSTEM |

|

| 5. |

CHECK KEY DIAGNOSTIC MODE |

(a) Check the following antennas in key diagnostic mode.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

| (1) Check the electrical key antenna (for driver door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly LH, check that the wireless buzzer sounds. HINT:

|

|

| (2) Check the electrical key antenna (for front passenger door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly RH, check that the wireless buzzer sounds. HINT:

|

|

| (3) Check the No. 1 indoor electrical key antenna assembly (front floor): When the electrical key transmitter sub-assembly is at either inspection point, check that the wireless buzzer sounds. HINT:

|

|

| (4) Check the No. 3 indoor electrical key antenna assembly (inside luggage compartment): When the electrical key transmitter sub-assembly is at either inspection point, check that the wireless buzzer sounds. HINT:

|

|

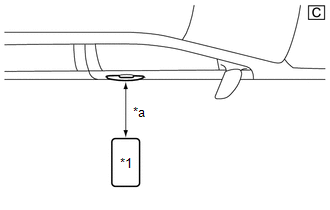

| (5) Check the electrical key antenna (outside luggage compartment): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the electrical key antenna (outside luggage compartment), check that the wireless buzzer sounds. HINT:

OK: Wireless buzzer sounds. |

|

|

Result | Proceed to |

|---|---|

|

Key diagnostic mode inspections fail for both channels |

A |

| Key diagnostic mode inspections succeed for both channels |

B |

| Key diagnostic mode inspection succeeds for only one of the channels |

C |

| B |

.gif) | GO TO STEP 18 |

| C |

.gif) | GO TO STEP 26 |

|

| 6. |

CHECK WAVE ENVIRONMENT |

(a) Bring the electrical key transmitter sub-assembly near the electrical key and tire pressure warning ECU and receiver and perform a wireless operation 2 or more times*.

- *: When the wireless function is operated, channel 1 and 2 are used alternately. If the first wireless operation is performed successfully and the second wireless operation fails, wave interference may be occurring for either channel.

HINT:

- When the electrical key transmitter sub-assembly is brought near the electrical key and tire pressure warning ECU and receiver, the possibility of wave interference decreases, and it can be determined if wave interference is causing the problem symptom.

- If the inspection result is that the problem only occurs in certain locations or at certain times of day, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

- There may be wave interference if the vehicle is near broadcasting antennas, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc. In this case, move the vehicle to a different location and check if there is any improvement.

- If a tool for checking radio waves, such as a signal strength meter, is available, move around the area while observing both the LF band (used by the vehicle antenna to form the detection area) and RF band (used by the electrical key transmitter sub-assembly for transmission) to check for locations where there is wave interference.

|

Result | Proceed to |

|---|---|

|

Wireless function does not operate normally |

A |

| Wireless function operates normally |

B |

| B |

.gif) | AFFECTED BY WAVE INTERFERENCE |

|

| 7. |

CHECK TRANSMITTER BATTERY |

(a) Check the transmitter battery level of the electrical key transmitter sub-assembly that was checked first.

(1) Press and hold the lock switch of the electrical key transmitter sub-assembly for 5 seconds and check the number of times that the LED illuminates.

HINT:

- The electrical key transmitter sub-assembly sends voltage information to the certification ECU (smart key ECU assembly) when it is being used. "Yes" is displayed for the Data List item "Key Low Battery" when this voltage information indicates 2.2 V or less.

Click here

.gif)

- Even if the transmitter battery is depleted, it is still possible to start the engine by holding the electrical key transmitter sub-assembly near the engine switch, depressing the brake pedal and pressing the engine switch.

|

Result | Proceed to |

|---|---|

|

LED illuminates 3 times or more when switch is pressed and held |

A |

| LED does not illuminate when switch is pressed and held |

B |

| LED illuminates once or twice but not a third time |

C |

| B |

.gif) | GO TO STEP 17 |

| C |

.gif) | REPLACE TRANSMITTER BATTERY |

|

| 8. |

CHECK ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

(a) Check if there is another electrical key transmitter sub-assembly available that is already registered to the vehicle.

|

Result | Proceed to |

|---|---|

|

Another registered electrical key transmitter sub-assembly is not available |

A |

| Another registered electrical key transmitter sub-assembly is available |

B |

| B |

.gif) | GO TO STEP 10 |

|

| 9. |

ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY REGISTRATION (NEW ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY) |

(a) Register a new electrical key transmitter sub-assembly.

HINT:

Refer to registration.

Click here .gif)

|

| 10. |

CHECK ENTRY OPERATION |

(a) Using another registered electrical key transmitter sub-assembly, check that the function operates normally.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

.gif) | END (ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY WAS DEFECTIVE) |

|

| 11. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER AND BODY GROUND) |

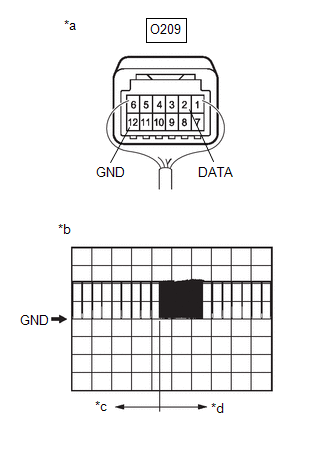

(a) Disconnect the O200 certification ECU (smart key ECU assembly) connector.

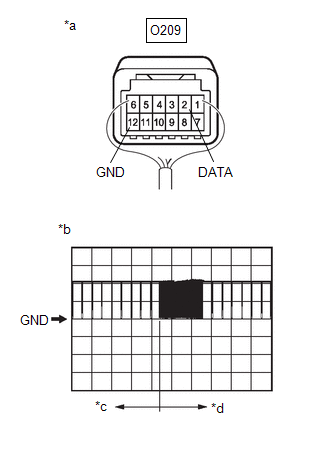

(b) Disconnect the O209 electrical key and tire pressure warning ECU and receiver connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

O200-21 (RCO) - O209-8 (+5) |

Always | Below 1 Ω |

|

O200-11 (RDAM) - O209-2 (DATA) |

Always | Below 1 Ω |

|

O200-12 (CSEL) - O209-6 (CSEL) |

Always | Below 1 Ω |

|

O209-12 (GND) - Body ground |

Always | Below 1 Ω |

|

O200-21 (RCO) or O209-8 (+5) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

O200-11 (RDAM) or O209-2 (DATA) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

O200-12 (CSEL) or O209-6 (CSEL) - Other terminals and body ground |

Always | 10 kΩ or higher |

(d) Reconnect the O200 certification ECU (smart key ECU assembly) connector.

(e) Reconnect the O209 electrical key and tire pressure warning ECU and receiver connector.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 12. |

CHECK ENTRY OPERATION |

(a) Connect all connectors and check that the function operates normally.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

.gif) | END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 13. |

CHECK ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER |

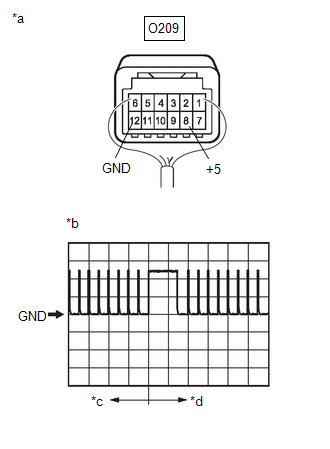

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

O209-12 (GND) - Body ground |

Always | Below 1 Ω |

| (b) Using an oscilloscope, check the waveform. OK:

|

|

| NG | .gif) | REPLACE ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 14. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| (b) Using an oscilloscope, check the waveform. OK:

|

|

| NG | .gif) | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 15. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) and perform registration again.

HINT:

Refer to registration.

Click here

.gif)

|

| 16. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the wireless function operates normally.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

.gif) | END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

.gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| 17. |

INSPECT TRANSMITTER BATTERY |

(a) Inspect the transmitter battery.

Click here .gif)

NOTICE:

Do not wrap the lead wire around a terminal, wedge it between terminals, or solder it. The terminal may be deformed or damaged, and the transmitter battery will not be able to be installed correctly.

| OK | .gif) | REPLACE ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

| NG | .gif) | REPLACE TRANSMITTER BATTERY |

| 18. |

PERFORM REGISTRATION |

(a) Perform registration of the B code.

HINT:

Refer to registration (ECU CODE REGISTRATION).

Click here

.gif)

|

| 19. |

CHECK ENTRY OPERATION |

(a) After completing B code registration, check that the entry lock and unlock functions can be operated 2 times consecutively.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

.gif) | END (B CODE REGISTRATION FAILED) |

|

| 20. |

READ VALUE USING GTS (B CODE REGISTERED) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Smart Key > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

B Code Registered | B code registration status |

No or Yes | No: B code is not registered properly Yes: B code is registered properly |

- |

|

Tester Display |

|---|

| B Code Registered |

|

Result | Proceed to |

|---|---|

|

"Yes" is displayed on the GTS |

A |

| "No" is displayed on the GTS |

B |

| B |

.gif) | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 21. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Measure the voltage while checking the Data List on the GTS.

(1) Read the Data List according to the display on the GTS.

|

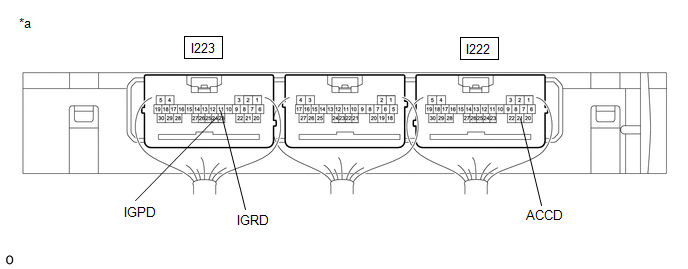

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

- | - |

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Power Supply Condition |

Power supply state | OFF, ACC ON, IGR ON, IGP ON or Starter ON |

OFF: Ignition switch off ACC ON: Ignition switch ACC IGR ON: Ignition switch ON IGP ON: Ignition switch ON Starter ON: Sending engine start request signal |

- |

|

Tester Display |

|---|

| Power Supply Condition |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I223-11 (IGRD) - Body ground |

Ignition switch off | Below 1 V |

|

Ignition switch ACC | Below 1 V | |

|

Ignition switch ON | 9 V or higher | |

|

I223-24 (IGPD) - Body ground |

Ignition switch off | Below 1 V |

|

Ignition switch ACC | Below 1 V | |

|

Ignition switch ON | 9 V or higher | |

|

I222-21 (ACCD) - Body ground |

Ignition switch off | Below 1 V |

|

Ignition switch ACC | 8.5 V or higher | |

|

Ignition switch ON | 8.5 V or higher |

| NG | .gif) | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 22. |

READ VALUE USING GTS (IGR POWER) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Main Body > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

IGR Power | Ignition switch status |

OFF or ON | OFF: Ignition switch off ON: Ignition switch ON |

- |

|

Tester Display |

|---|

| IGR Power |

HINT:

If the certification ECU (smart key ECU assembly) misjudges for any reason that the ignition switch is ON even though the ignition switch is off, the entry lock and unlock functions will be disabled.

|

Result | Proceed to |

|---|---|

|

The main body ECU (multiplex network body ECU) judges properly that the power source is off when the ignition switch is off |

A |

| The main body ECU (multiplex network body ECU) does not judge properly that the power source is off when the ignition switch is off |

B |

| B |

.gif) | TROUBLESHOOT MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 23. |

CHECK ENTRY OPERATION |

(a) Disconnect and reconnect the certification ECU (smart key ECU assembly) connectors.

(b) Check that the function operates normally.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

.gif) | END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 24. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) with a new one and perform registration again.

HINT:

Refer to registration.

Click here

.gif)

|

| 25. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the function operates normally.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

.gif) | END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

.gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| 26. |

CHECK WAVE ENVIRONMENT |

(a) Bring the electrical key transmitter sub-assembly near the electrical key and tire pressure warning ECU and receiver and perform a wireless operation 2 or more times*.

- *: When the wireless function is operated, channel 1 and 2 are used alternately. If the first wireless operation is performed successfully and the second wireless operation fails, wave interference may be occurring for either channel.

HINT:

- When the electrical key transmitter sub-assembly is brought near the electrical key and tire pressure warning ECU and receiver, the possibility of wave interference decreases, and it can be determined if wave interference is causing the problem symptom.

- If the inspection result is that the problem only occurs in certain locations or at certain times of day, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

- There may be wave interference if the vehicle is near broadcasting antennas, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc. In this case, move the vehicle to a different location and check if there is any improvement.

- If a tool for checking radio waves, such as a signal strength meter, is available, move around the area while observing both the LF band (used by the vehicle antenna to form the detection area) and RF band (used by the electrical key transmitter sub-assembly for transmission) to check for locations where there is wave interference.

|

Result | Proceed to |

|---|---|

|

Wireless door lock function does not operate normally |

A |

| Wireless door lock function operates normally |

B |

| B |

.gif) | AFFECTED BY WAVE INTERFERENCE |

|

| 27. |

CHECK ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

(a) Check if there is another electrical key transmitter sub-assembly available that is already registered to the vehicle.

|

Result | Proceed to |

|---|---|

|

Another registered electrical key transmitter sub-assembly is not available |

A |

| Another registered electrical key transmitter sub-assembly is available |

B |

| B |

.gif) | GO TO STEP 29 |

|

| 28. |

ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY REGISTRATION (NEW ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY) |

(a) Register a new electrical key transmitter sub-assembly.

HINT:

Refer to registration.

Click here .gif)

|

| 29. |

CHECK KEY DIAGNOSTIC MODE |

(a) Enter key diagnostic mode and select the channel for which the wireless door lock buzzer did not sound and perform the inspection again using a different electrical key transmitter sub-assembly than was used in the initial inspection.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

|

Result | Proceed to |

|---|---|

|

Wireless buzzer does not sound |

A |

| Wireless buzzer sounds |

B |

| B |

.gif) | END (ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY WAS DEFECTIVE) |

|

| 30. |

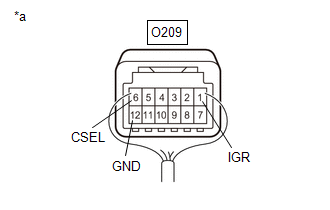

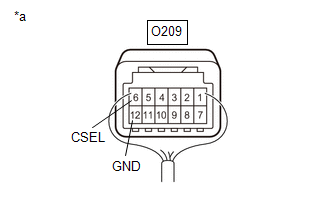

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER) |

(a) Disconnect the O209 electrical key and tire pressure warning ECU and receiver connector.

(b) Disconnect the O200 certification ECU (smart key ECU assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

O209-6 (CSEL) - O200-12 (CSEL) |

Always | Below 1 Ω |

|

O209-6 (CSEL) or O200-12 (CSEL) - Other terminals and body ground |

Always | 10 kΩ or higher |

(d) Reconnect the O209 electrical key and tire pressure warning ECU and receiver connector.

(e) Reconnect the O200 certification ECU (smart key ECU assembly) connector.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 31. |

CHECK ENTRY OPERATION |

(a) Connect all connectors and check that the function operates normally.

Click here .gif)

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

.gif) | END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 32. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) | REPLACE CERTIFICATION ECU |

|

| 33. |

CHECK ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER |

(a) Enter key diagnostic mode and select the channel for which the wireless buzzer did not sound.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

| (b) Using an oscilloscope, check the waveform. OK:

HINT: Inspection should be performed while the electrical key antenna check in key diagnostic mode is being performed on the failed channel (the channel in which the buzzer did not sound). |

|

| NG | .gif) | REPLACE ELECTRICAL KEY AND TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 34. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) and perform registration again.

HINT:

- For replacement

Click here

.gif)

- Refer to registration.

Click here

.gif)

|

| 35. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the function operates normally.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

.gif) | END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

.gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

.gif)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)